The exquisite mechanical principle of self-locking design

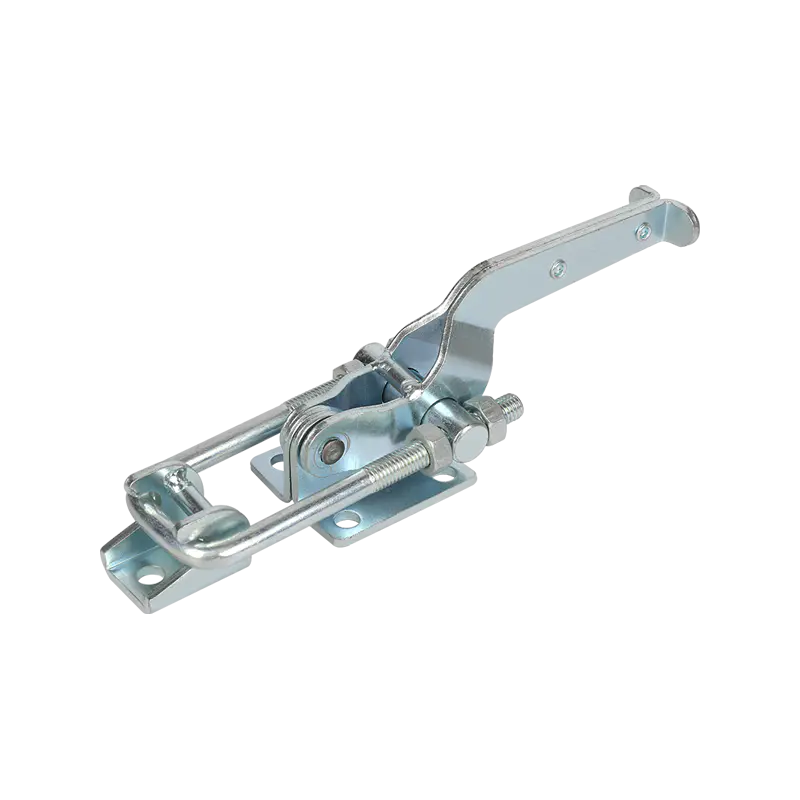

The self-locking function of 40323 adjustable U bolt self locking toggle clamps comes from its exquisite and complex mechanical structure design. The U-bolt serves as the basic framework, encircling the fixed object, and the threads at both ends create conditions for adjusting the tightening force and range. What really gives it the self-locking ability is the self-locking toggle mechanism. This mechanism cleverly uses the principle of leverage to generate a strong clamping force with a small external force. When the operator applies force through the handle, the toggle starts to move and gradually approaches the mechanical dead point. Once the mechanical dead point is crossed, the toggle clamp enters the locked state, and the internal mechanical structure interacts with each other to generate strong friction. This friction is like an invisible yoke, tightly binding the fixed object, making it difficult to move, and achieving a stable tightening effect.

The exquisiteness of this design lies in that it converts external force into mutual constraints of internal structure to form a stable mechanical balance. In the locked state, even if the external force tries to move the fixed object, the self-locking characteristics of the mechanical structure will further enhance the internal friction, thus forming a state of "the more force, the more stable", which greatly improves the reliability of fastening.

Excellent anti-loosening performance under different working conditions

In actual application scenarios, the working conditions faced by mechanical devices are complex and diverse. The self-locking design of the adjustable U-bolt self-locking toggle clamp has demonstrated strong anti-loosening capabilities under various harsh conditions.

When facing severe vibration conditions, such as mining machinery, construction equipment, etc., continuous and strong vibration will be generated during the operation of the equipment, which is a great test for the fastening stability of the components. The traditional fastening method is prone to loosening of nuts and displacement of bolts under long-term vibration, which may cause the components to fall off, thereby causing equipment failure. After the adjustable U-bolt self-locking toggle clamp is locked, its internal self-locking structure can effectively offset the impact of vibration. The locking of the mechanical dead point position, combined with strong friction, allows the fixed object to remain in place in a vibrating environment, ensuring that the various components of the equipment are tightly connected, maintaining the normal operation of the equipment, and reducing the maintenance cost and downtime caused by loosening.

Under conditions of strong impact, such as automobile collision test equipment, stamping machinery, etc., the instantaneous strong impact force will exert a huge force on the fastening components. If the fastening device cannot withstand this impact, the components may loosen or even be damaged, which will not only affect the normal use of the equipment, but also may bring safety hazards. The adjustable U-bolt self-locking toggle clamp has a unique self-locking design. When it is impacted, the internal structure can quickly convert the impact force into a power to enhance friction. Even in the face of a huge instantaneous impact force, the toggle clamp can still tightly lock the fixed object, ensure the integrity and stability of the equipment structure, effectively avoid safety accidents caused by looseness, and provide reliable safety protection for operators and equipment.

For working conditions that need to withstand long-term external forces, such as temporary support structures in bridge construction and long-term fixed parts of large mechanical equipment, traditional fastening methods may cause fatigue loosening due to long-term stress, resulting in reduced fastening effect. The self-locking design of the adjustable U-bolt self-locking toggle clamp can always maintain a stable fastening state under long-term external force. Its internal mechanical structure will not fail due to long-term stress, and the continuously generated friction ensures that the fixed object will not loosen or move, providing a solid guarantee for the long-term stable operation of the project and equipment.

Comparison of advantages with traditional fastening methods

Compared with traditional bolt and nut fastening, welding and other methods, the self-locking design of the adjustable U-bolt self-locking toggle clamp has significant advantages. Although the traditional bolt and nut fastening method is widely used, it is easy for the nut to loosen when facing complex working conditions. Even if anti-loosening measures such as spring washers are used, the anti-loosening effect will be greatly reduced under long-term vibration or impact. The self-locking design of the adjustable U-bolt self-locking toggle clamp fundamentally solves the loosening problem through the locking of the mechanical structure and the strong friction force, and can achieve a more reliable fastening effect without the need for additional anti-loosening devices.

As a permanent fastening method, welding has a firm connection but lacks flexibility. Once the welding is completed, the position and state of the components are difficult to change, and the welding process may have a certain impact on the material of the components, reducing their performance. The adjustable U-bolt self-locking toggle clamp is different. It not only has a strong fastening ability, but also can easily fix objects of different sizes and shapes by adjusting the U-bolt and toggle mechanism. When disassembly is required, the operation is simple and will not cause damage to the fixed object, greatly improving the convenience and flexibility of use.

Industry News

Home / News / Industry News / How does the unique self-locking design of 40323 Adjustable U Bolt Self Locking Toggle Clamps solve the problem of loosening of mechanical fastening?

Industry News

May 15, 2025 POST BY ADMIN

How does the unique self-locking design of 40323 Adjustable U Bolt Self Locking Toggle Clamps solve the problem of loosening of mechanical fastening?

Message Feedback

News & EVENT

Product Categories

Recent Posts

If You Are Interested

In Our Products,

Please Consult Us

In Our Products,

Please Consult Us

Copyright © 2023 Shanghai Bingshuo Hardware & Machinery Co., Ltd. All Rights Reserved.

OEM/ODM Industrial Stainless Steel Hardware Latch Toggle Clamp Suppliers

Privacy

English

English Español

Español русский

русский