1. Strictly follow the assembly criteria of design requirements

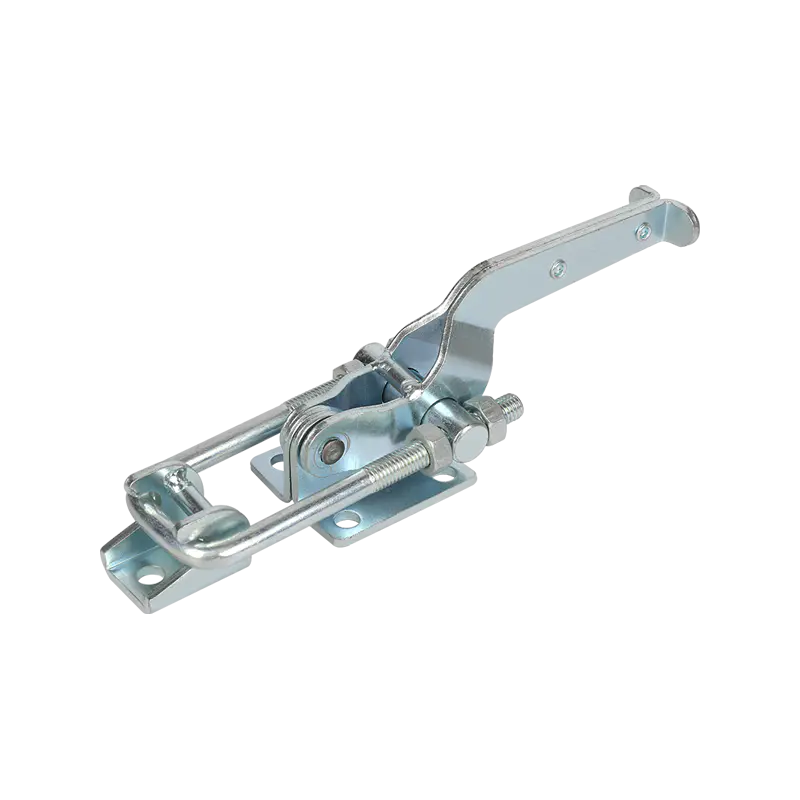

The assembly of the horizontal toggle clamp of Horizontal Toggle Clamp For Jig Construction follows strict design specifications from the beginning. The design drawings are like the "construction blueprint" of the clamp assembly, which details the position, size and assembly sequence of each component. The assembler needs to study the design drawings in depth and clarify the matching relationship between the components to ensure the smooth progress of the assembly work. When assembling the main frame of the clamp, plates and profiles of different specifications need to be spliced at specific angles and positions. Any deviation may affect the overall structural strength and stability of the clamp. Strictly assembling in accordance with the design requirements is the primary prerequisite for ensuring that the performance of the clamp meets expectations.

During the assembly process, the installation of each component has its own specific standards and specifications. Taking the hinged structure of the clamp as an example, the installation position of the sleeve and the pin directly affects the opening and closing flexibility of the clamp. If the sleeve is installed offset, the pin and sleeve will not fit well, causing the clamp to jam when opening and closing, and even affecting its service life. Therefore, the assembler needs to repeatedly confirm the installation position of each component according to the design drawings to ensure that it is completely consistent with the design requirements, laying the foundation for the stable operation of the clamp.

2. Application of special assembly tools and equipment

In order to ensure assembly accuracy, the assembly process of the horizontal articulated clamp is inseparable from special assembly tools and equipment. These tools and equipment are specially designed to meet the high-precision requirements of the assembly of clamp parts. When installing the hinged part of the clamp, a high-precision positioning fixture is required to fix the sleeve and pin. This fixture can accurately control the relative position of the sleeve and the pin to ensure that the two can achieve smooth relative movement after assembly. At the same time, special tightening tools are also indispensable. When tightening the bolt connection part, bolts of different specifications need to be tightened with a wrench of the corresponding torque to ensure that the tightening force of the bolt meets the design standard and avoid clamp failure due to loose bolts.

In addition to manual tools, some advanced assembly equipment is also widely used in the production of horizontal articulated clamps. The CNC assembly platform can accurately control the assembly position and angle of parts through the computer control system. When assembling complex jaw structures, the CNC assembly platform can automatically adjust the position of each part of the jaw according to the preset program to ensure that it can be accurately connected to the main frame and achieve the clamping performance required by the design. The application of these special tools and equipment has greatly improved the accuracy and efficiency of clamp assembly, making the quality of the clamp more stable and reliable.

3. Clearance control and monitoring of the articulated part

As the core of the flexible opening and closing of the horizontal articulated clamp, the assembly accuracy of the articulated part is crucial, and the matching clearance between the sleeve and the pin is the key parameter. If the clearance is too large, the clamp will shake during the opening and closing process, affecting the stability and accuracy of the clamp; if the clearance is too small, it is easy to generate excessive friction resistance, making it difficult to open and close the clamp, and may even damage the parts due to frictional heat. During the assembly process, the clearance needs to be monitored and adjusted in real time by precise measuring tools.

Common measuring tools include micrometers, feeler gauges, etc. Before installing the sleeve and pin, the assembler will first use a micrometer to measure the actual size of the sleeve inner diameter and the pin outer diameter, and select the appropriate sleeve and pin for matching according to the clearance range required by the design. During the assembly process, the gap between the sleeve and the pin is measured with a feeler gauge to ensure that the gap value is within the specified tolerance range. Once the gap is found to be not in compliance with the requirements, it is necessary to adjust it by grinding the inner wall of the sleeve or replacing the pin of the appropriate size until the gap reaches the design standard. This fine gap control and monitoring process ensures that the articulated part can achieve smooth and stable movement, providing a strong guarantee for the normal operation of the clamp.

IV. Quality control of the connection parts

The various connection parts of the horizontal articulated clamp, such as bolt connection, welding, etc., are the key to ensuring the overall structural strength and reliability of the clamp. In the bolted connection part, in addition to using special tools to control the tightening torque, it is also necessary to strictly control the material, specification and anti-loosening measures of the bolts. The bolts in different parts are made of materials with different strength grades according to their stress conditions to ensure that the clamp will not fail due to bolt breakage during work. At the same time, in order to prevent the bolts from loosening under vibration and other working conditions, anti-loosening methods such as spring washers and thread lockers will be used to further improve the reliability of the connection.

For the welding connection parts, the welding quality directly affects the structural strength of the clamp. The assemblers need to have professional welding skills and operate in strict accordance with the welding process requirements. Before welding, the welding parts should be cleaned to remove impurities such as oil and rust on the surface to ensure the welding quality. During the welding process, the parameters such as welding current, voltage and welding speed should be controlled to ensure that the weld is uniform and full, without defects such as pores and cracks. After welding is completed, the weld needs to be visually inspected and non-destructively tested, such as ultrasonic flaw detection and magnetic particle flaw detection, to ensure that the quality of the welding parts meets the requirements. Through strict quality control of the connection parts, the overall structural strength and reliability of the horizontal articulated clamp are effectively improved.

V. Application and advantages of automated assembly technology

Automated assembly technology has been widely used in the assembly process of some high-end horizontal articulated clamps. The automated assembly production line can realize the automatic grasping, positioning and assembly of parts through the coordinated work of robotic arms, sensors and computer control systems. During the assembly process, the robotic arm can accurately install parts such as sleeves and pins to the specified position according to the preset program, avoiding the errors that may be caused by manual operation. At the same time, the sensor can monitor various parameters in the assembly process in real time, such as position, pressure, temperature, etc. Once an abnormal situation is found, the system will automatically issue an alarm and stop assembly to ensure the assembly quality.

Automated assembly technology not only improves assembly efficiency, but also greatly improves the stability of assembly quality. Compared with manual assembly, automated assembly can reduce the impact of human factors on assembly accuracy and ensure that the assembly quality of each clamp meets high standards. Moreover, the automated assembly production line can achieve 24-hour continuous operation, greatly improving production efficiency and meeting the market's large demand for high-quality horizontal articulated clamps. With the continuous advancement of technology, the application of automated assembly technology in the field of horizontal articulated clamp manufacturing will be more extensive and in-depth.

Industry News

Home / News / Industry News / How does the horizontal toggle clamp of Horizontal Toggle Clamp For Jig Construction ensure stable performance through precise assembly?

Industry News

Jun 12, 2025 POST BY ADMIN

How does the horizontal toggle clamp of Horizontal Toggle Clamp For Jig Construction ensure stable performance through precise assembly?

Message Feedback

News & EVENT

Product Categories

Recent Posts

If You Are Interested

In Our Products,

Please Consult Us

In Our Products,

Please Consult Us

Copyright © 2023 Shanghai Bingshuo Hardware & Machinery Co., Ltd. All Rights Reserved.

OEM/ODM Industrial Stainless Steel Hardware Latch Toggle Clamp Suppliers

Privacy

English

English Español

Español русский

русский