1. Analysis of the working mechanism of the T-Shaped Handle 90°Vertical Quick Toggle Clamp

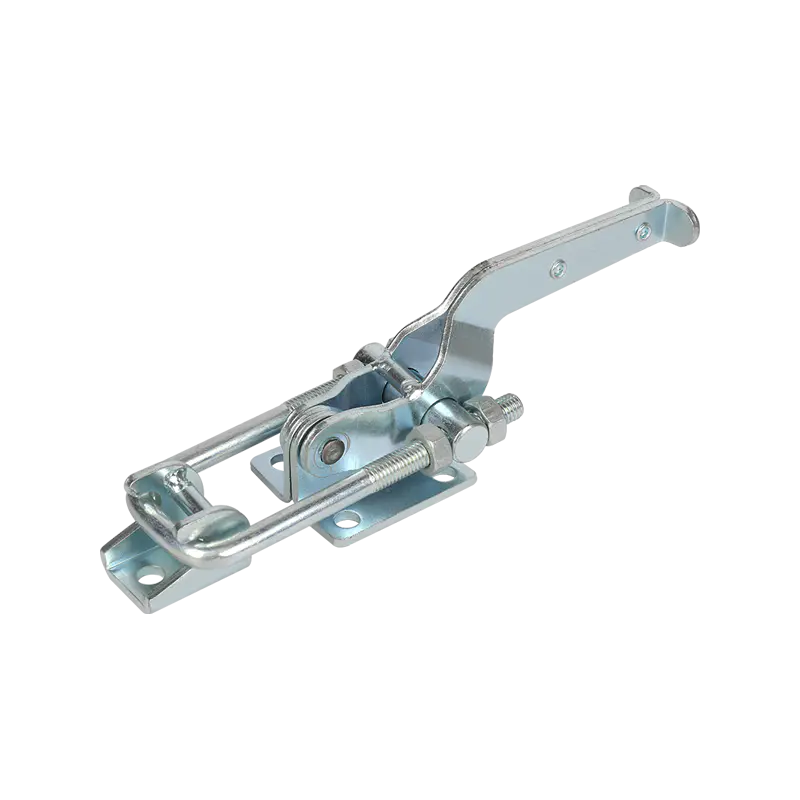

The T-Shaped Handle 90°Vertical Quick Toggle Clamp can operate efficiently due to its exquisite design and structure. It is based on specific mechanical principles and is mainly composed of core components such as the clamp body, T-handle, shaft and connecting rod. When the operator turns the T-handle, this action is quickly converted into a clamping force in the vertical direction through a cleverly designed connecting rod mechanism. When the handle is turned 90°, the clamp completes the entire process from loosening to clamping. This process is simple and smooth, and the power transmission is efficient and stable.

This design has significant advantages. First, the 90° rotation angle setting not only ensures the convenience of operation, but also ensures that the clamp can quickly reach the maximum clamping state, avoiding excessive operation and time waste. Secondly, the vertical force application method allows the clamp to fully play its role in a limited space, which is particularly suitable for use in some assembly scenarios with strict requirements on space utilization. For example, in the electronic equipment assembly workshop, the work surface space is compact. The vertical operation characteristics of the T-handle 90° vertical quick clamp enable workers to accurately fix small components such as circuit boards in a small space, greatly improving the flexibility of operation and space utilization.

2. T-handle 90° vertical quick clamp assists electronic equipment assembly

In the delicate field of electronic equipment assembly, the importance of T-handle 90° vertical quick clamp is self-evident. The core of electronic equipment - the circuit board, is densely distributed with various tiny and precise electronic components. When installing these components on the circuit board, the stable fixation of the circuit board is a prerequisite for ensuring the accuracy of component installation.

The T-handle 90° vertical quick clamp can provide stable and reliable fixing force. It can firmly fix the circuit board on the workbench, and the circuit board will not move at all whether it is soldering components or plugging and unplugging operations. When welding tiny chip resistors and capacitors, if the circuit board shakes, problems such as cold welding and short circuit may occur at the welding points, seriously affecting the performance of electronic equipment. The T-handle 90° vertical quick clamp can effectively avoid such situations, help workers to accurately complete welding work, and greatly improve welding quality and efficiency.

In the process of electronic equipment assembly, the product update speed is very fast, which requires the assembly process to have a high degree of flexibility. The T-handle 90° vertical quick clamp can easily adapt to circuit boards of different sizes and shapes. By adjusting the opening size of the clamp or replacing specific chuck accessories, it can quickly adapt to new circuit board specifications without large-scale adjustments to the entire assembly process, providing strong support for the rapid iteration production of electronic equipment.

3. T-handle 90° vertical quick clamp enables furniture manufacturing and assembly

In the furniture manufacturing industry, the T-handle 90° vertical quick clamp is also an indispensable assistant. In the process of furniture assembly, various types of wood and boards need to be precisely spliced and fixed to ensure the final furniture product has a stable structure and beautiful appearance.

When splicing multiple wooden boards into a furniture frame, the T-handle 90° vertical quick clamp can clamp the wooden boards from different directions so that the wooden boards fit tightly and seamlessly. This not only ensures the structural strength of the frame, but also avoids appearance defects such as large gaps caused by loose splicing. When making a solid wood dining table frame, using multiple T-handle 90° vertical quick clamps can firmly fix the table legs and the tabletop frame together, ensure the squareness of the frame, and improve the overall quality of the dining table.

Furniture manufacturing technology is constantly innovating, and various new materials and complex structures are constantly emerging. The T-handle 90° vertical quick clamp can cope with these changes with its strong adaptability. For some furniture parts made of new composite materials, the clamp will not damage the surface of the material while providing sufficient clamping force. When assembling modern minimalist style furniture with unique shapes, the clamp can be flexibly adjusted according to the shape and angle of the parts to achieve precise positioning and clamping to meet the diverse needs of furniture manufacturing.

4. Overview of the assembly advantages of T-handle 90° vertical quick clamps

The biggest advantage of T-handle 90° vertical quick clamps in product assembly is that they can greatly improve efficiency. Traditional clamping tools, such as ordinary bench vises, require operators to spend a lot of time tightening when clamping workpieces, and the operation process is relatively cumbersome. However, with T-handle 90° vertical quick clamps, operators only need to simply turn the T-handle to complete the clamping action in a very short time. On the electronic equipment assembly line, each quick clamping operation can save valuable time for subsequent processes. With the accumulation of many assembly links, the overall production efficiency will be significantly improved.

In the product assembly process, the positioning accuracy of the workpiece directly affects the product quality. T-handle 90° vertical quick clamps fully consider the accuracy requirements during the design and manufacturing process. Through precise processing technology, the clamp jaws can accurately fit the surface of the workpiece to ensure that the workpiece is in a precise position when clamped. In the assembly of precision instruments, even extremely small position deviations may cause a significant decline in instrument performance. T-handle 90° vertical quick clamps can control the positioning error of the workpiece within a very small range, providing a solid guarantee for the production of high-precision products.

The environment for product assembly is complex and diverse. Different industries and different production scenarios have different requirements for the durability and adaptability of clamps. T-handle 90° vertical quick clamps are extremely sophisticated in material selection. The main body is mostly made of high-strength metals, such as carbon steel and stainless steel, which have excellent strength and toughness, can withstand large clamping forces, and are not easy to deform. In some assembly lines where clamps need to be used frequently, the clamps can still maintain good working performance after long periods of high-intensity work. For some special environments, such as humid furniture manufacturing workshops, stainless steel clamps can effectively resist corrosion and ensure long-term stable operation.

English

English Español

Español русский

русский