-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

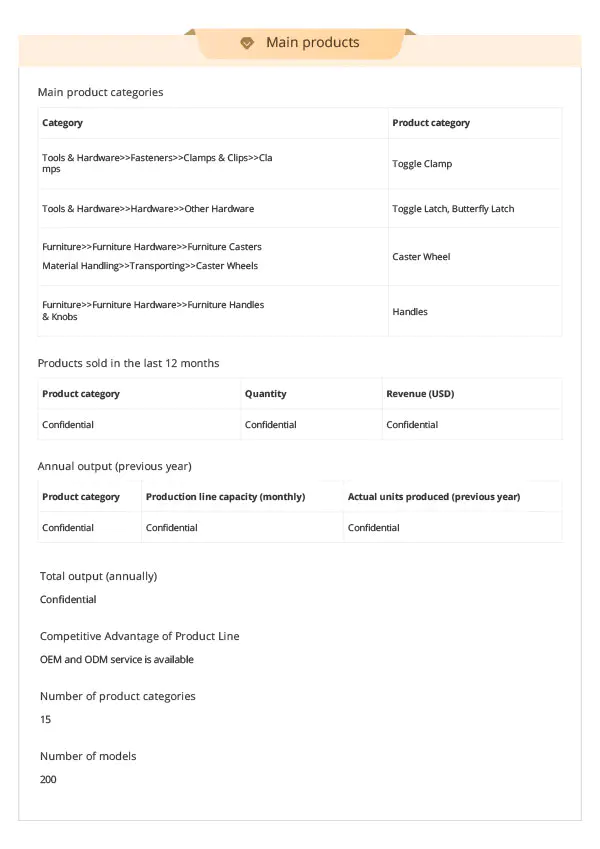

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

Why do non-adjustable toggle latch still have a place in automatic weapons and precision machinery?

In the long history of mechanical design and manufacturing, various sophisticated locking mechanisms have emerged in an endless stream, and they ensure the stability and safety of mechanical devices in their own unique ways. Among them, the non-adjustable toggle latch, as an ancient and classic locking mechanism, has left a deep mark in many fields with its unique principle and stable performance.

The history of the non-adjustable toggle latch can be traced back to the late 19th century, when the mechanical manufacturing industry was in a stage of rapid development. In order to meet the needs of automatic weapons and precision machinery for high-precision locking mechanisms, engineers began to seek new design ideas. Against this background, the non-adjustable toggle latch came into being.

Its design inspiration comes from the human elbow joint, and the locking and unlocking of the mechanical device are achieved by simulating the movement of the elbow joint. This design idea is not only simple and intuitive, but also shows extremely high stability and reliability in practical applications. The non-adjustable toggle latch has been widely used in automatic weapons, precision machinery and other fields.

The principle of the non-adjustable toggle latch is mainly based on the lever principle and hinge connection. It consists of two or more connecting parts, one of which is a fixed rod and the other is a rocker. The rocker is connected to the fixed rod through a hinge and can rotate within a certain range. When the rocker rotates around the hinge, the part fixed on the rocker will produce linear motion, thereby achieving locking or unlocking.

Specifically, in a non-adjustable toggle latch, one end of the rocker is usually connected to the moving part of the mechanical device, and the other end is connected to the fixed rod through a hinge. When the mechanical device needs to be locked, the moving part pushes the rocker to rotate around the hinge, so that the other end of the rocker fits tightly with the fixed rod to form a stable locked state. At this time, due to the constraint of the hinge, the rocker cannot continue to rotate, thereby ensuring the stability of the mechanical device.

When unlocking is required, the rocker is rotated in the opposite direction around the hinge through external force or the release mechanism inside the mechanical device, thereby releasing the fit state with the fixed rod. At this time, the moving part of the mechanical device can move freely to achieve unlocking.

The non-adjustable toggle latch has the characteristics of simple structure, good stability and high reliability. Because its principle is simple and intuitive, and the manufacturing and maintenance costs are relatively low, it has been widely used in many fields.

In the field of automatic weapons, non-adjustable toggle locks are widely used in the locking mechanisms of weapons such as rifles and machine guns. By simulating the movement of the human elbow joint, the weapon can be quickly locked and unlocked, which improves the shooting accuracy and reliability of the weapon.

In the field of precision machinery, non-adjustable toggle locks are also widely used in high-precision mechanical devices such as CNC machine tools and automation equipment. Through its stable locking performance, the stability and precision of the mechanical device during the processing are ensured.

Non-adjustable toggle locks also have certain versatility and portability. Through simple modifications and adjustments, they can adapt to the needs of different fields and different mechanical devices.

As an ancient and classic locking mechanism, the non-adjustable toggle latch has left a deep mark in many fields with its unique principle and stable performance. With the advancement of science and technology and the development of the manufacturing industry, non-adjustable toggle latch will continue to play an important role in mechanical design and manufacturing.

English

English Español

Español русский

русский