-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

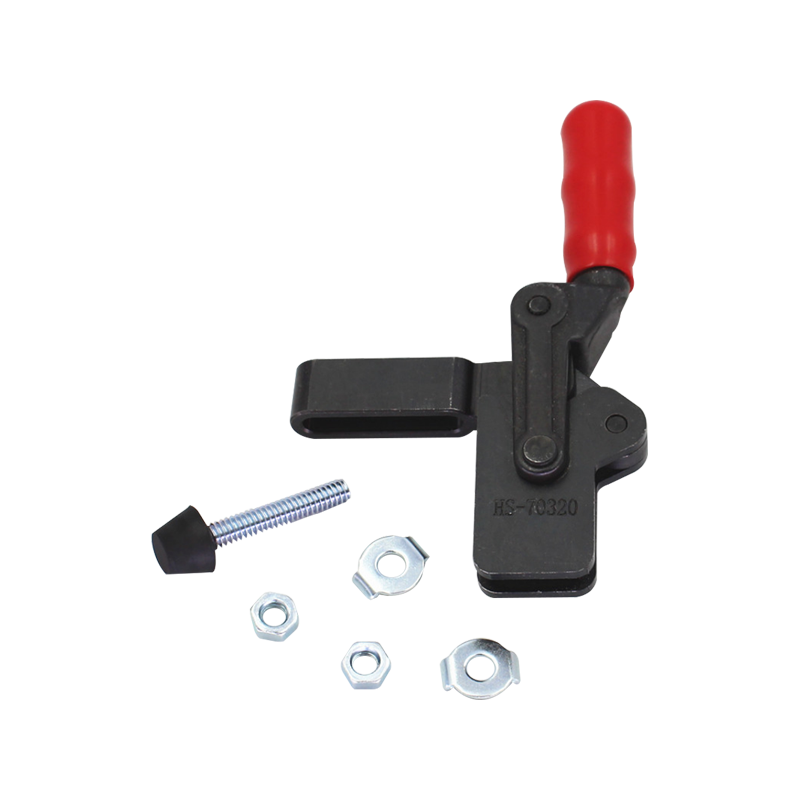

What are the advantages of Vertical Toggle Clamp in industrial manufacturing?

Vertical Toggle Clamp has the following advantages in industrial manufacturing:

Efficient clamping capacity: Vertical Toggle Clamp can provide strong clamping force to ensure that the workpiece is firmly fixed in the required position, which is suitable for processes requiring high precision and high stability.

Easy to operate: Using Vertical Toggle Clamp, you can clamp and release the workpiece quickly and easily, improve production efficiency, and reduce operator fatigue.

High space utilization: Due to its vertical clamping design, Vertical Toggle Clamp can still work effectively even when space is limited, suitable for various workbench and equipment layouts.

Wide applicability: It can be used for clamping workpieces of various sizes and shapes, including irregular shapes and fragile materials, making it widely applicable in diverse manufacturing environments.

Reliability and durability: Vertical Toggle Clamp is usually made of durable materials, with a simple but stable and reliable design structure, which can work stably for a long time and reduce the need for maintenance and replacement.

Strong automation integration: In the automated production line, Vertical Toggle Clamp can be integrated with automated equipment to improve overall production efficiency and consistency.

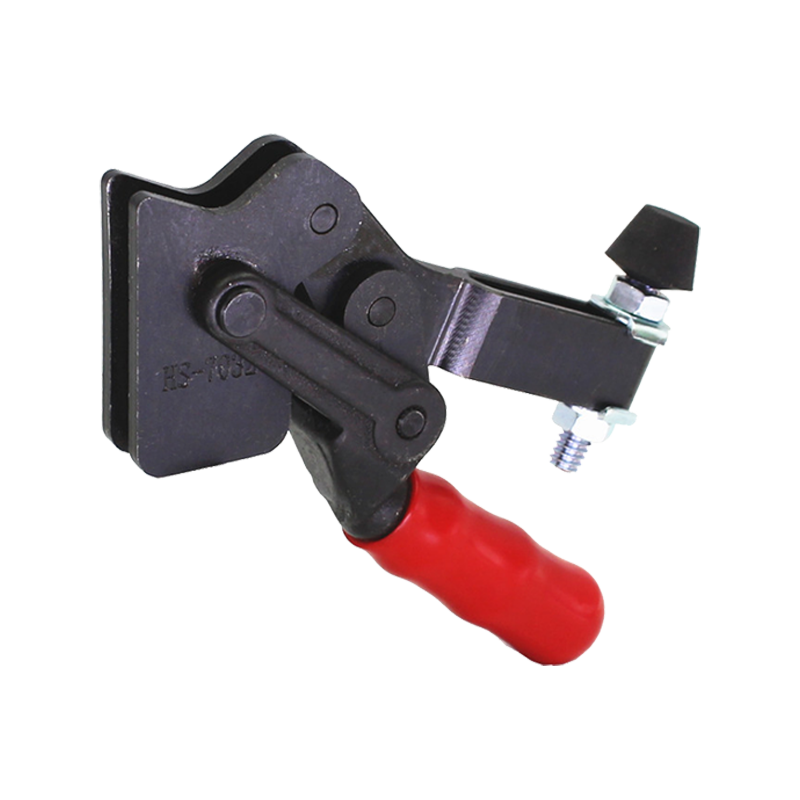

What are the key steps to pay attention to when installing and adjusting the Vertical Toggle Clamp?

When installing and adjusting the Vertical Toggle Clamp, you need to pay attention to the following key steps:

Choose a suitable installation location: Determine the location where the Toggle Clamp is installed to ensure that it can effectively clamp the workpiece and is easy to operate.

Fix the mounting base: Secure the base or mounting plate of the Toggle Clamp to the workbench or equipment to ensure its stability and safety.

Adjust the clamping force: Adjust the clamping force of the Toggle Clamp according to the needs of the workpiece. This is usually achieved by adjusting the handle or bolt to ensure that the workpiece is not clamped too tight or too loose.

Check the clamping angle and position: Ensure that the workpiece is in the correct position and angle when the Toggle Clamp is clamped to avoid mis-clamping or loose clamping.

Test the clamping effect: Before formal use, test the clamping effect to confirm that the Toggle Clamp can stably clamp the workpiece and operate smoothly.

Keep Parts Clean and Lubricated: Clean the various parts of the Toggle Clamp regularly and make sure to lubricate them when necessary to maintain their normal operation and extend their life.

Follow our Guidelines: Follow our installation and adjustment guidelines for the Toggle Clamp to ensure optimal safety and performance.

English

English Español

Español русский

русский