-

2010

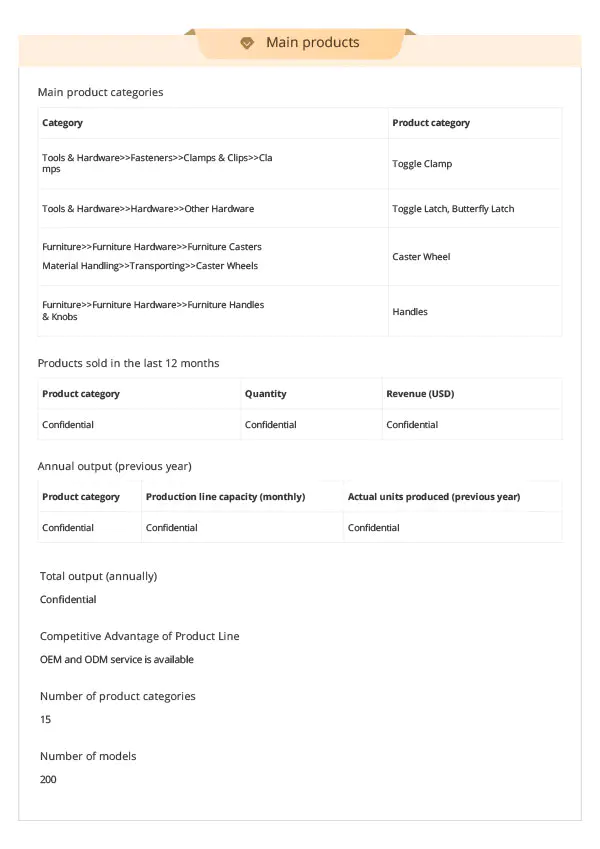

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

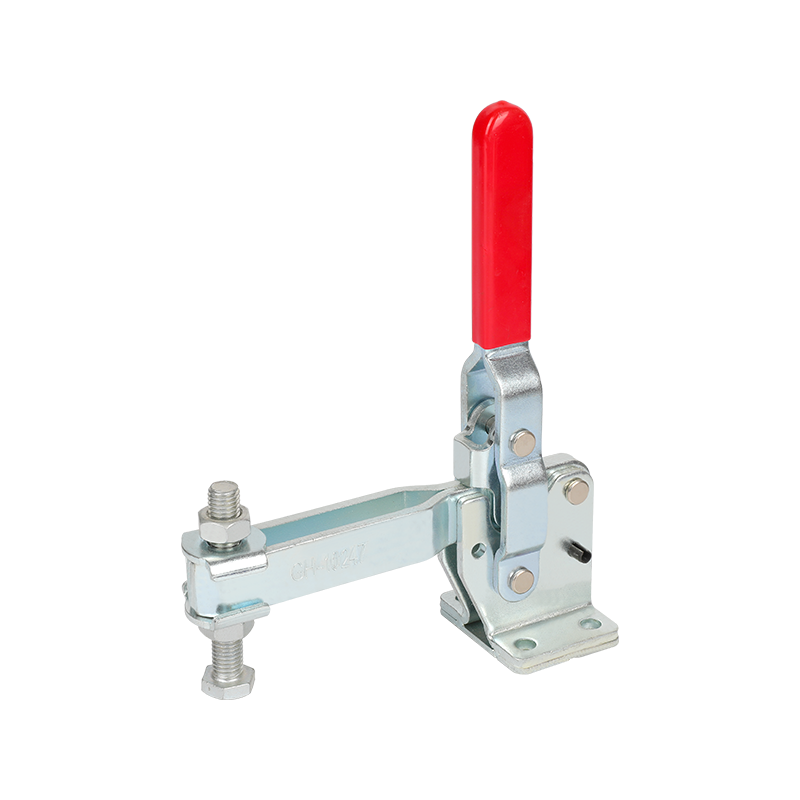

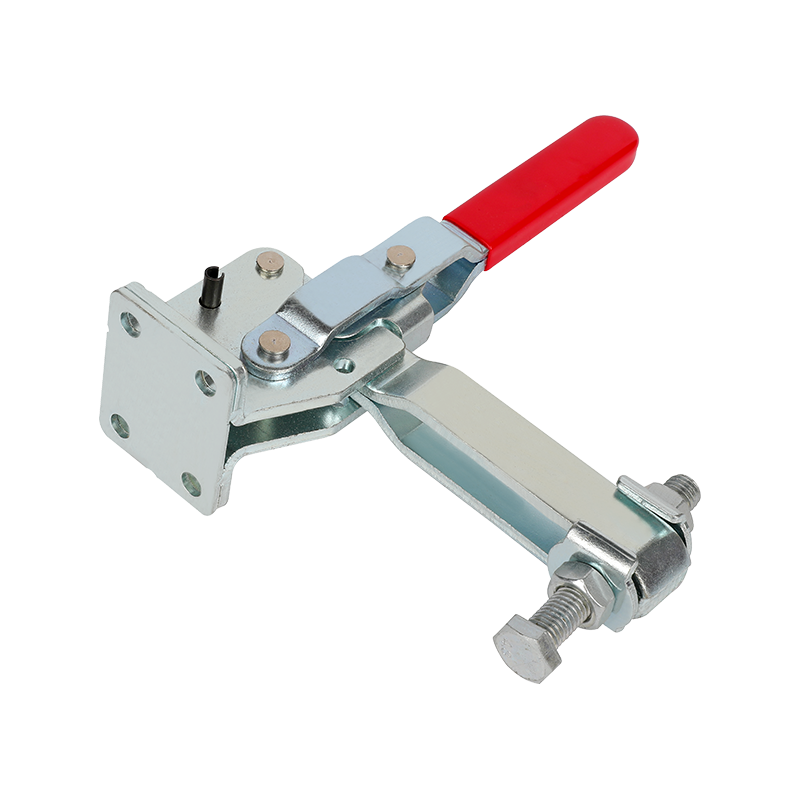

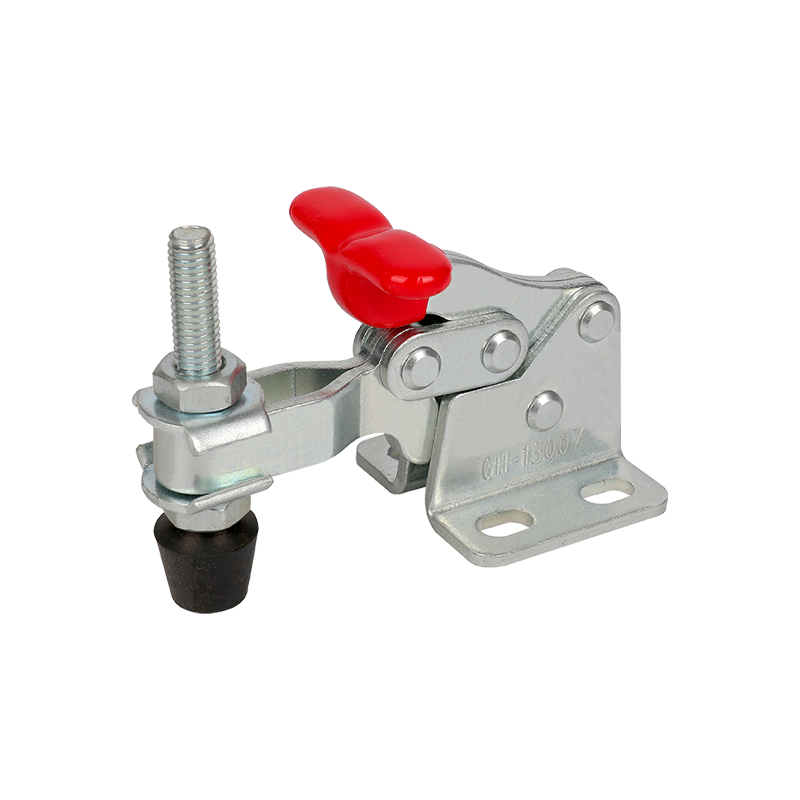

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

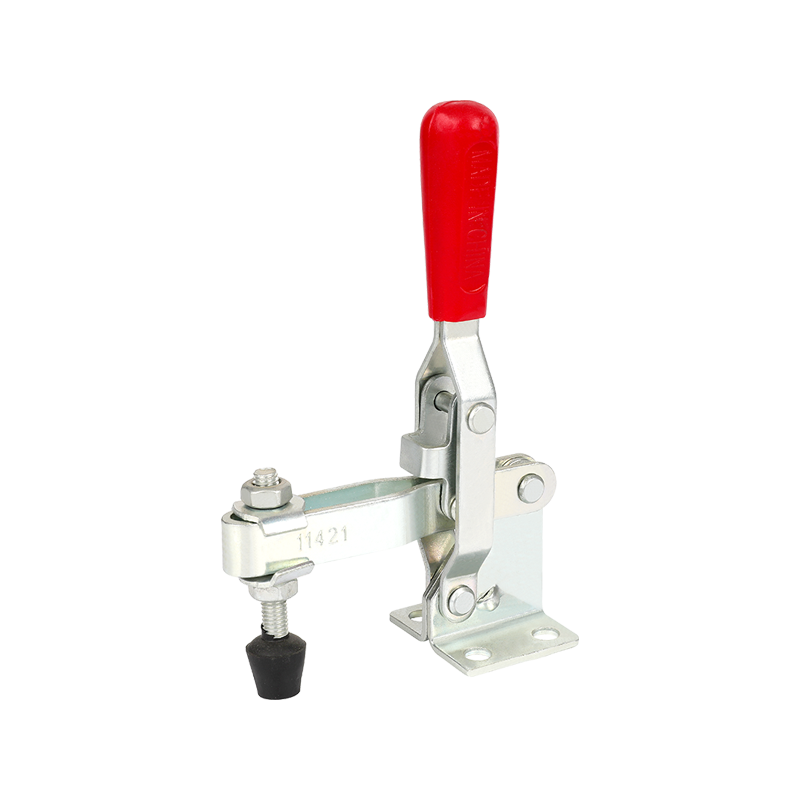

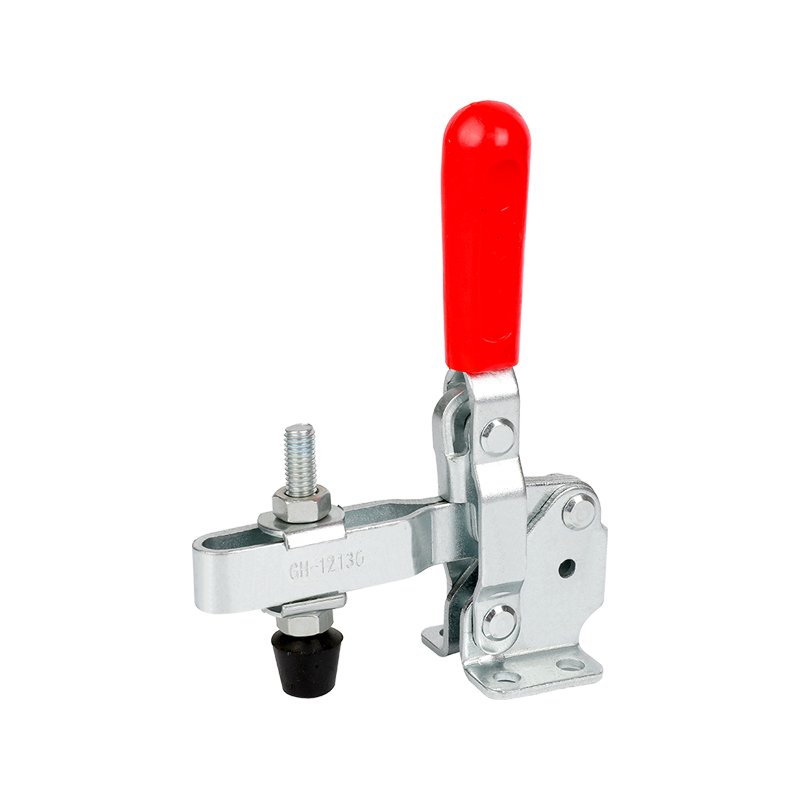

As technology evolves, what are some possible improvements to the vertical toggle clamp?

1. Material optimization and lightweighting

As new materials continue to emerge, the material choices for vertical toggle clamps will become more diverse. First of all, the use of high-strength, lightweight materials such as carbon fiber composite materials, aluminum alloys, etc. can not only improve the overall strength of the clamp, but also significantly reduce its weight, making operation more convenient. At the same time, the application of new materials can also improve the corrosion resistance and wear resistance of the fixture and extend its service life.

2. Intelligent control

With the rapid development of industrial automation and intelligent manufacturing, intelligent control of vertical toggle clamps will become an important direction for future improvements. By integrating smart components such as sensors, actuators, and controllers, functions such as automatic positioning, automatic clamping, and automatic detection of fixtures are realized. This will greatly improve production efficiency and product quality, and reduce the difficulty and errors of manual operations.

3. Precise control of clamping force

The clamping force of a vertical toggle clamp is one of the important indicators of its performance. Clamping force refers to the force generated by the vertical toggle clamp when clamping the workpiece, which is used to ensure that the workpiece remains stable during processing. Proper clamping force can prevent the workpiece from moving, vibrating or deforming during processing, thereby ensuring processing accuracy and product quality. Factors such as the structure, size and material of the toggle clamp will affect its clamping force. A properly designed toggle clamp can provide a more stable and uniform clamping force to meet the clamping needs of different workpieces. Different operating modes (such as manual, pneumatic, electric, etc.) have an impact on the size and stability of the clamping force. For example, manual operation may be affected by human factors, while pneumatic or electric operation is more stable and reliable. Different operating modes (such as manual, pneumatic, electric, etc.) have an impact on the size and stability of the clamping force. For example, manual operation may be affected by human factors, while pneumatic or electric operation is more stable and reliable.

4. Multifunctional design

In order to meet the needs of different working conditions, vertical toggle clamps can be developed in the direction of multi-functional design. For example, develop fixtures with multiple clamping methods to adapt to workpieces of different shapes and sizes; or integrate other auxiliary functions, such as rotation, swing, etc., to meet more complex operating requirements.

5. Modular design

Modular design is a method of decomposing a complex system into several relatively independent modules. For vertical toggle clamps, adopting a modular design can make its structure more flexible, easy to maintain and upgrade. By decomposing the fixture into different functional modules, it can be easily replaced, repaired and upgraded to adapt to the needs of different working conditions.

6. Energy saving and environmental protection

Today, when environmental protection and energy saving have become the focus of global attention, the energy saving and environmental protection performance of vertical toggle clamps will also become an important direction for future improvement. For example, energy-saving motors and transmission mechanisms that reduce energy loss are used to reduce the energy consumption of fixtures; at the same time, the fixture structure and materials used are optimized to reduce waste emissions and environmental pollution during the production process.

7. Humanized design

Humanized design refers to fully considering human factors in the design process to make the product more in line with people's usage habits and physiological characteristics. For vertical toggle clamps, measures such as a more ergonomic handle design and added safety protection devices can be adopted to improve the safety and comfort of operation.

English

English Español

Español русский

русский