-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

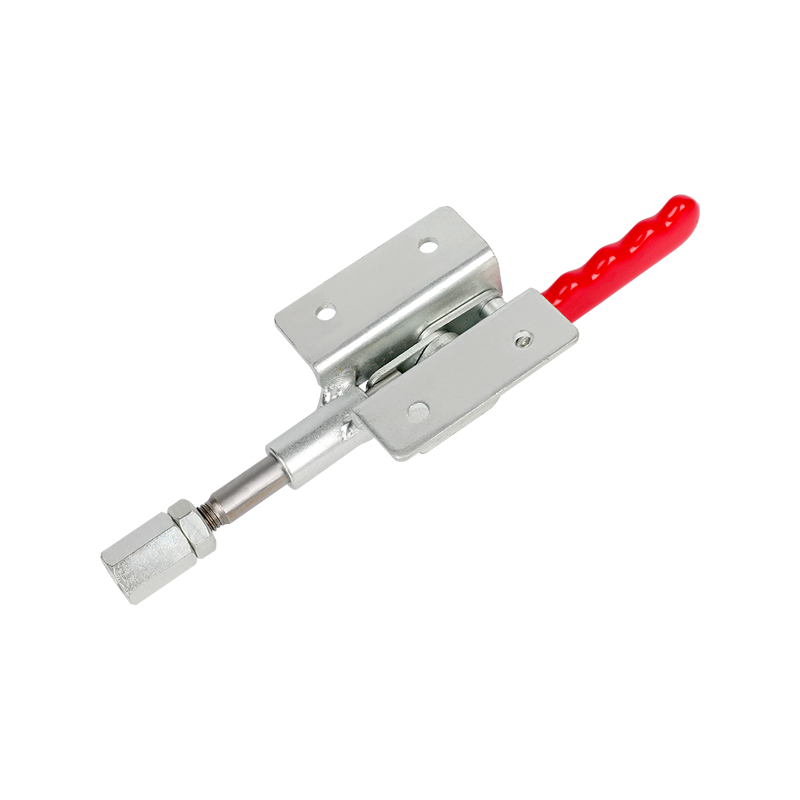

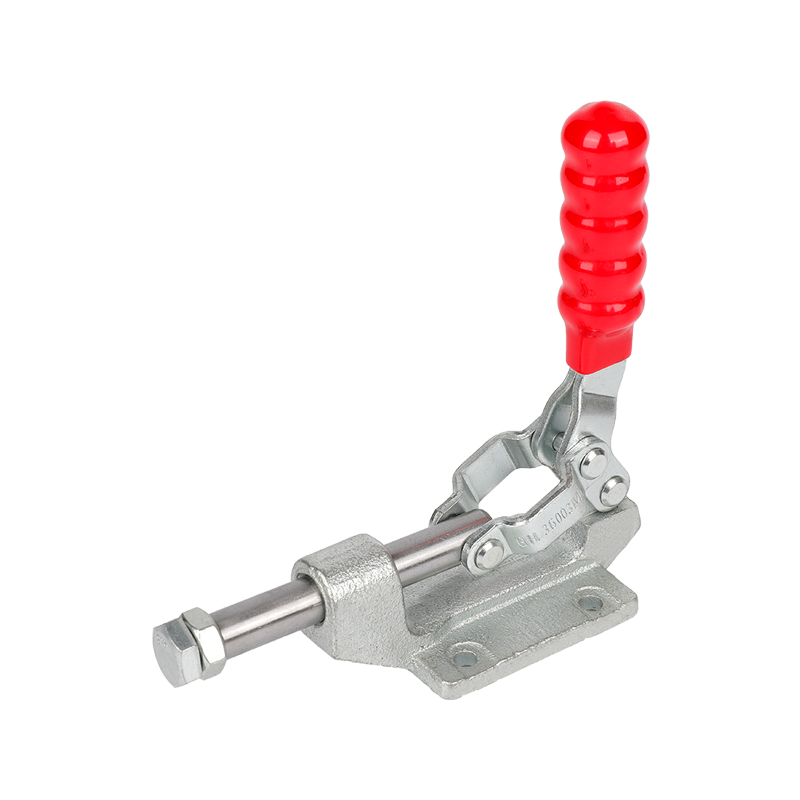

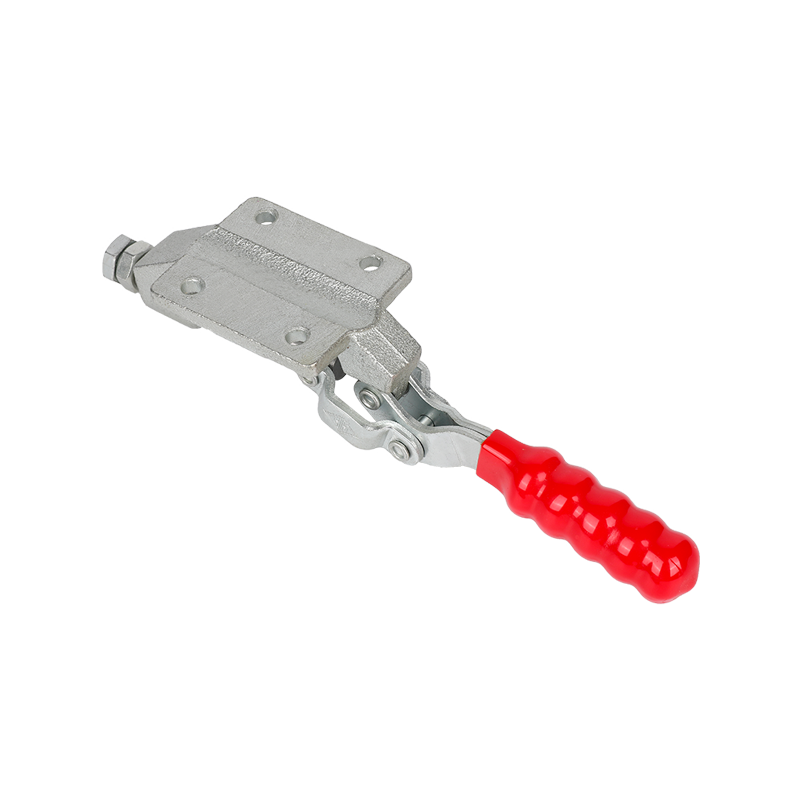

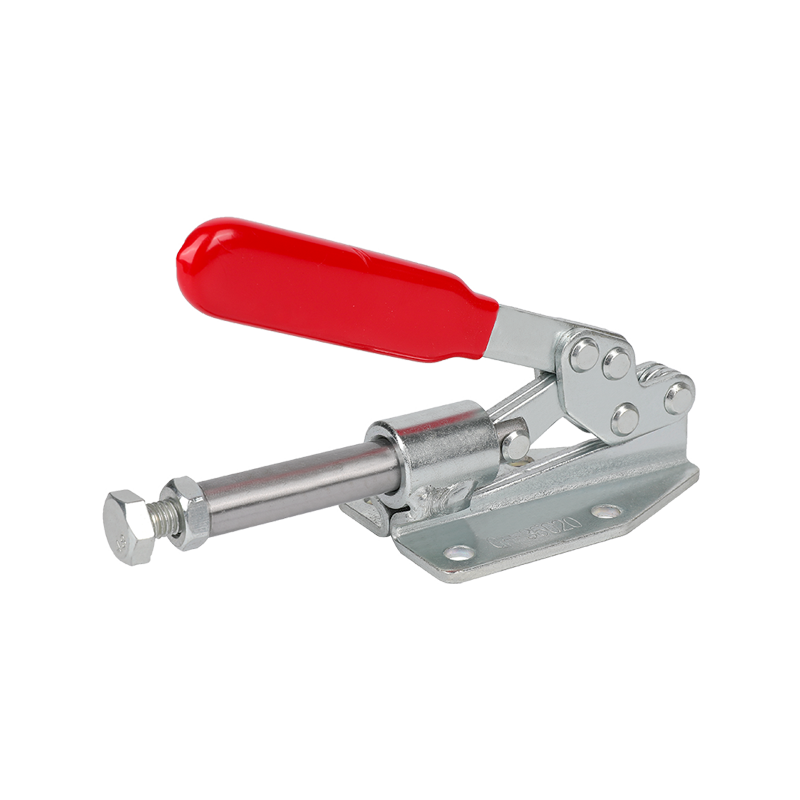

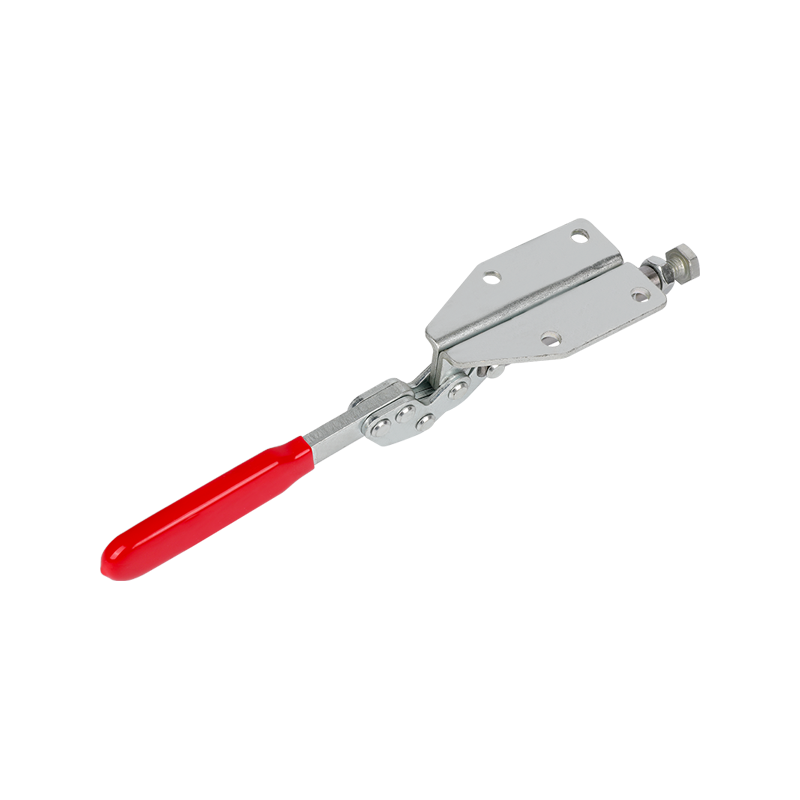

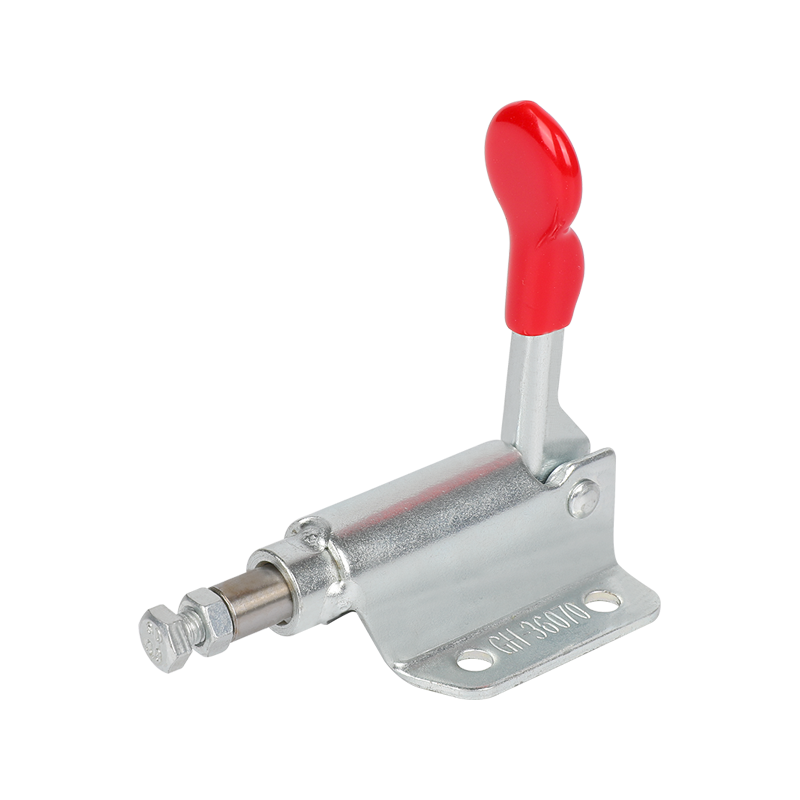

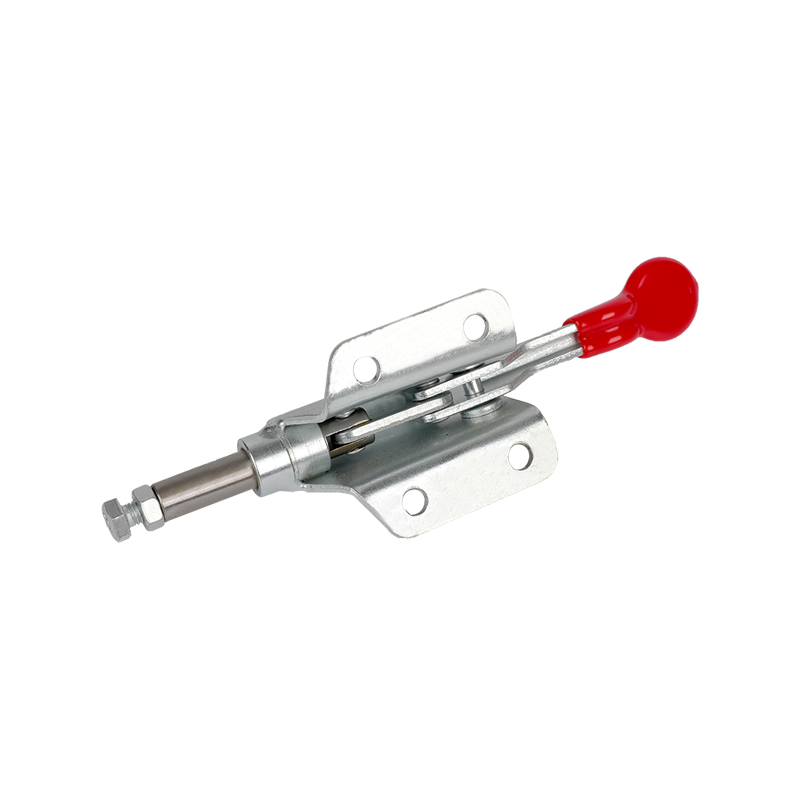

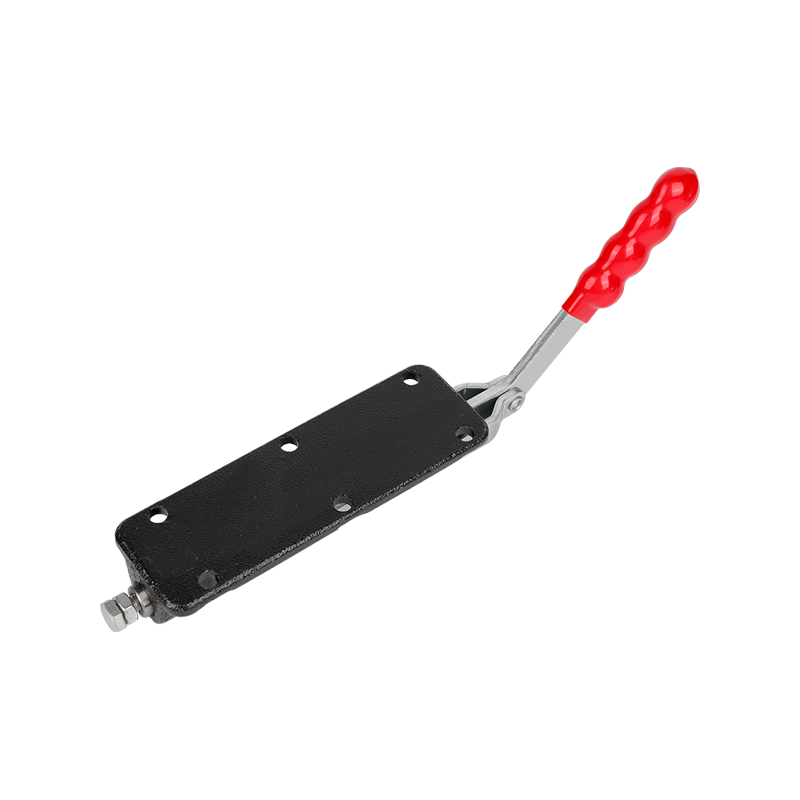

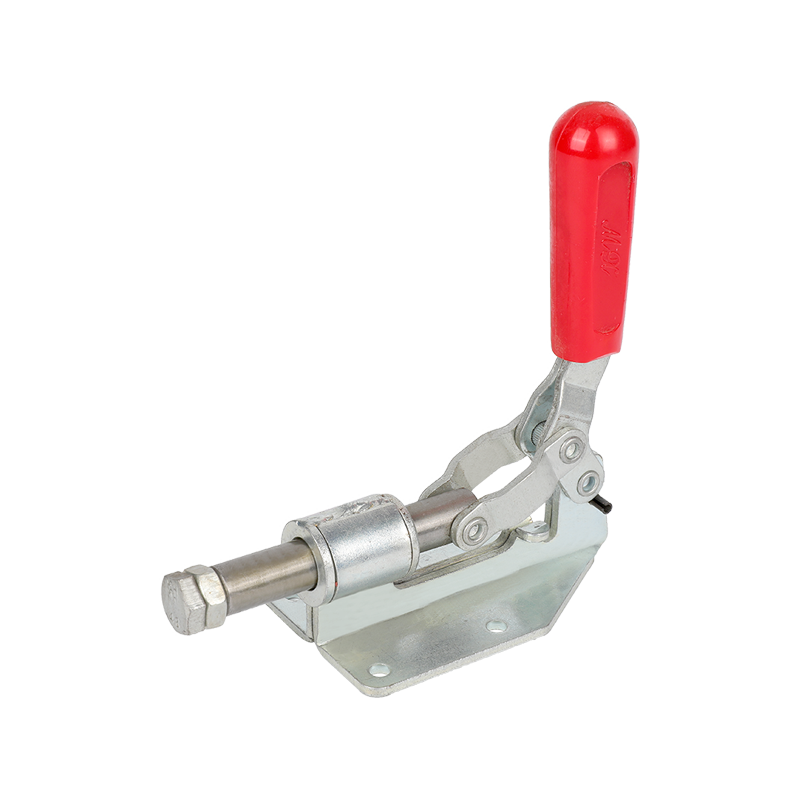

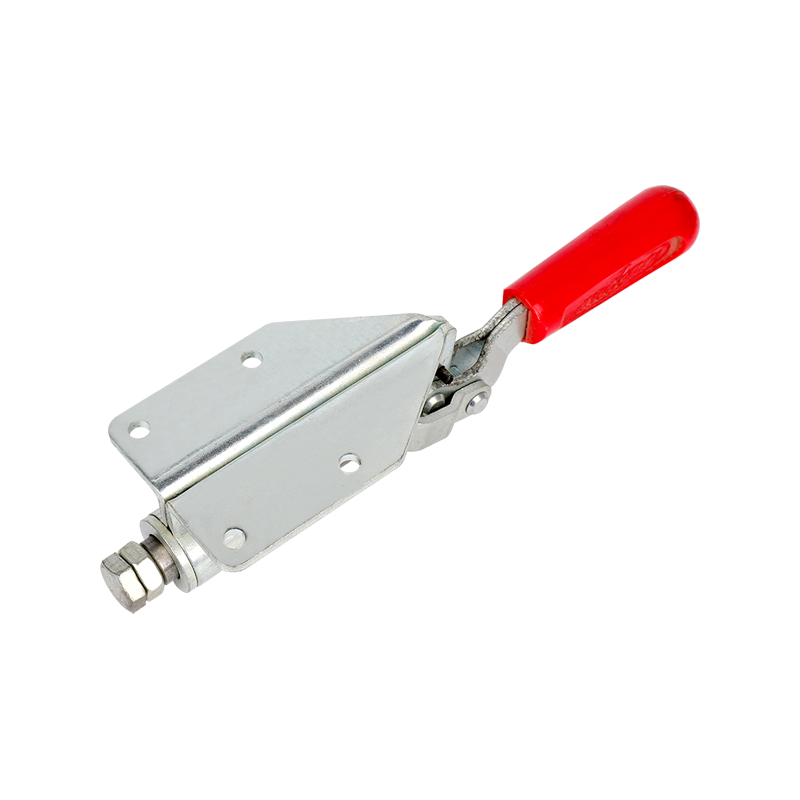

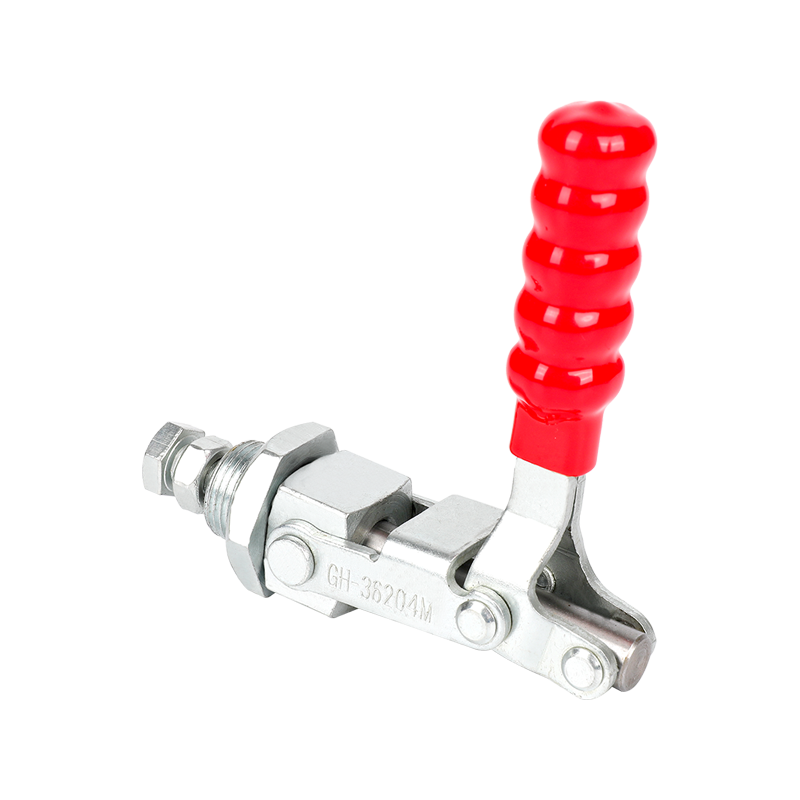

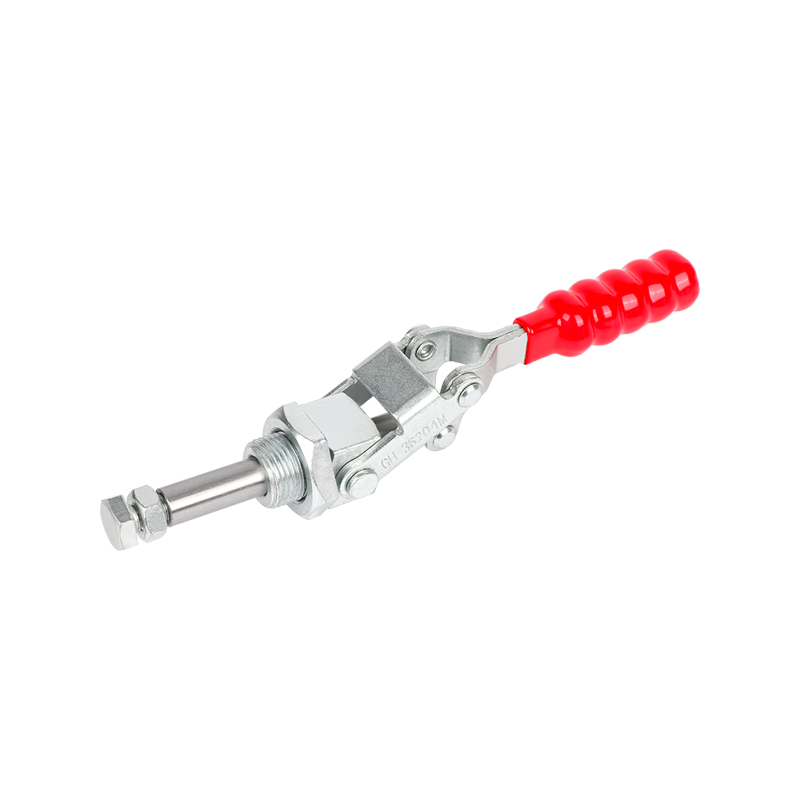

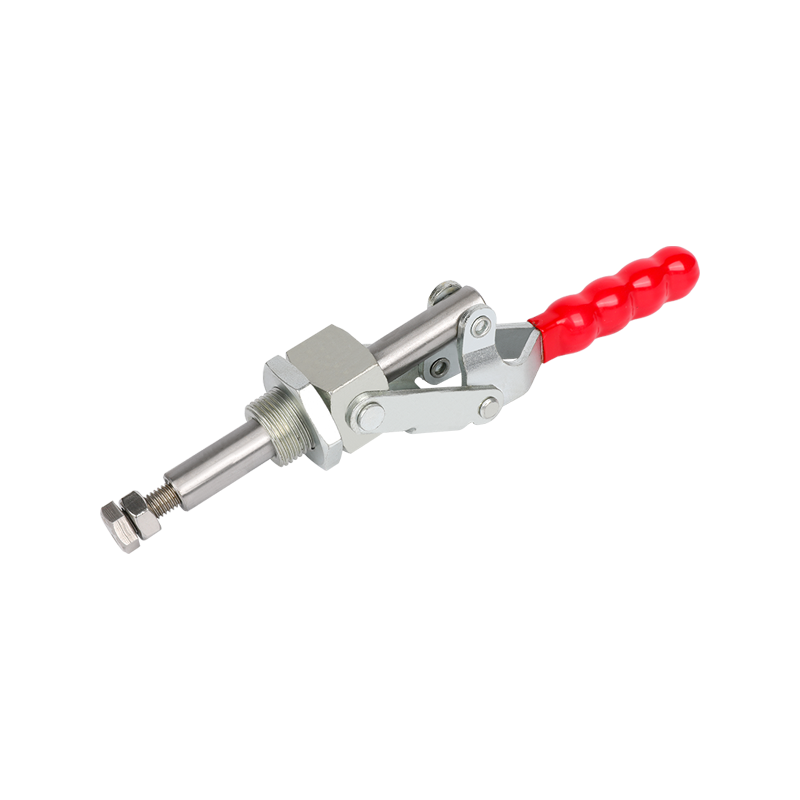

How to operate the Push pull toggle clamp correctly?

Push pull toggle clamp is a clamping device widely used in industry and manufacturing. It is designed to provide a fast and efficient clamping solution while ensuring safe and reliable operation.

1. Preparation

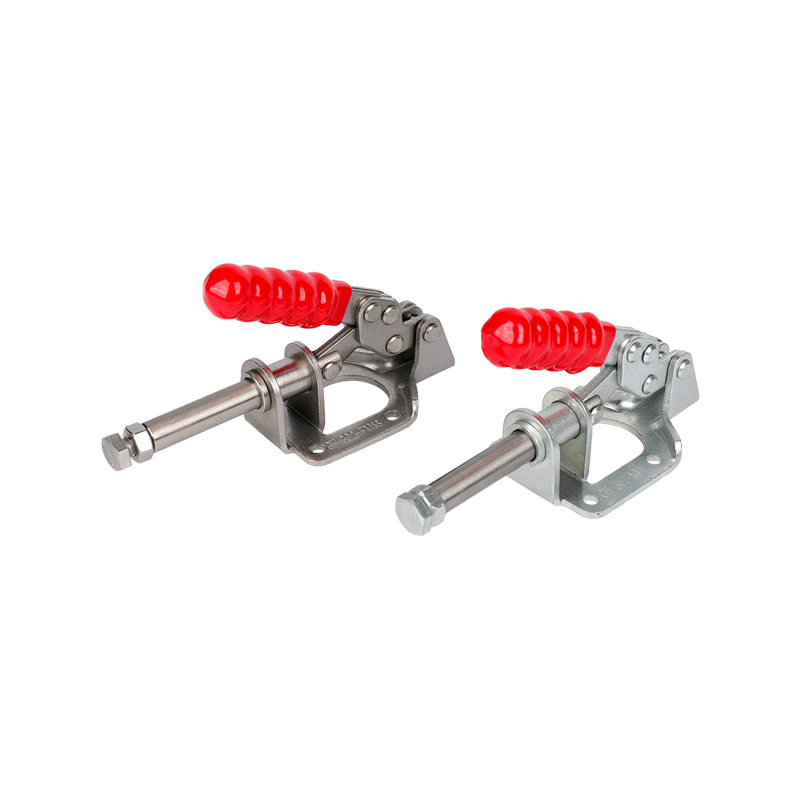

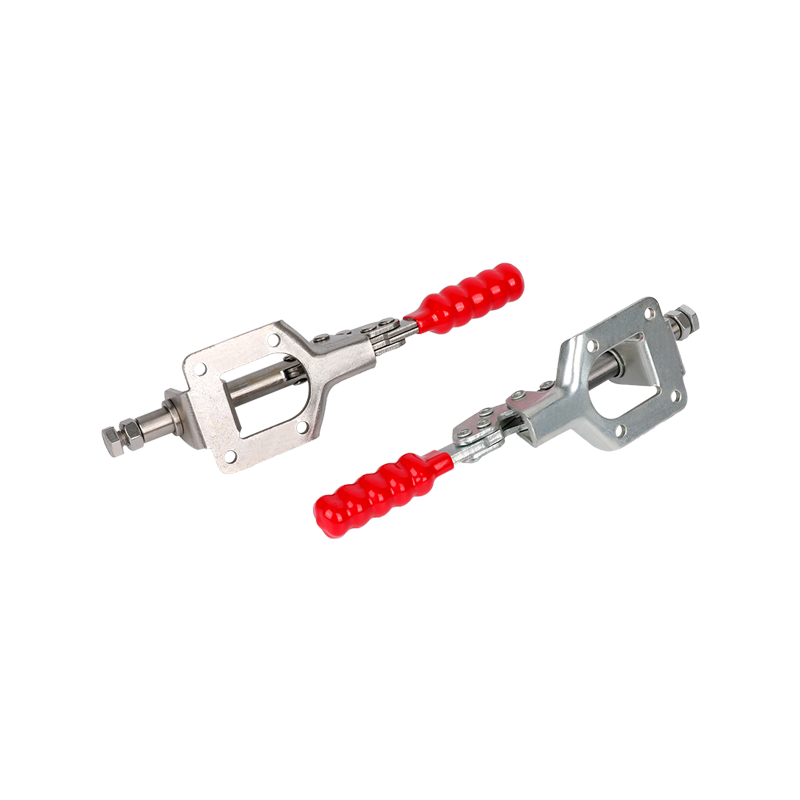

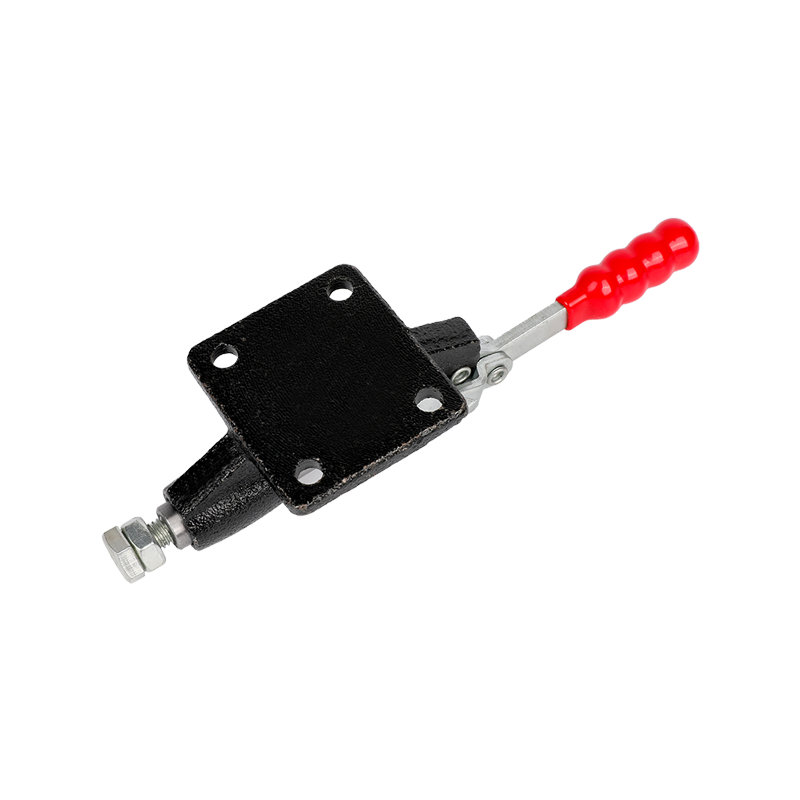

Choose the right clamp: Choose the right Push pull toggle clamp model according to the size, shape and required clamping force of the clamped workpiece. Push pull toggle clamp has different clamping ranges to accommodate workpieces of different sizes. You need to make sure that the clamping range of the selected clamp is greater than or equal to the diameter or width of the workpiece you want to clamp. Different clamp models have different clamping forces. The required clamping force needs to be determined based on the size, weight and shape of the workpiece. The shape of the workpiece is also a factor to consider when choosing a clamp. Some clamp designs are more suitable for clamping workpieces of specific shapes, such as symmetrical, asymmetrical, tubular, spherical or conical workpieces.

Check the clamp status: Before operation, carefully check whether the various parts of the clamp are intact, such as the handle, pressure head screw, locking mechanism, etc. If there is any damage or abnormality, it should be replaced or repaired in time.

Adjust the position of the clamp: Place the clamp in a suitable position to ensure that there is no obstacle between the clamp and the workpiece when clamping the workpiece, and it is convenient to operate.

2. Operation steps

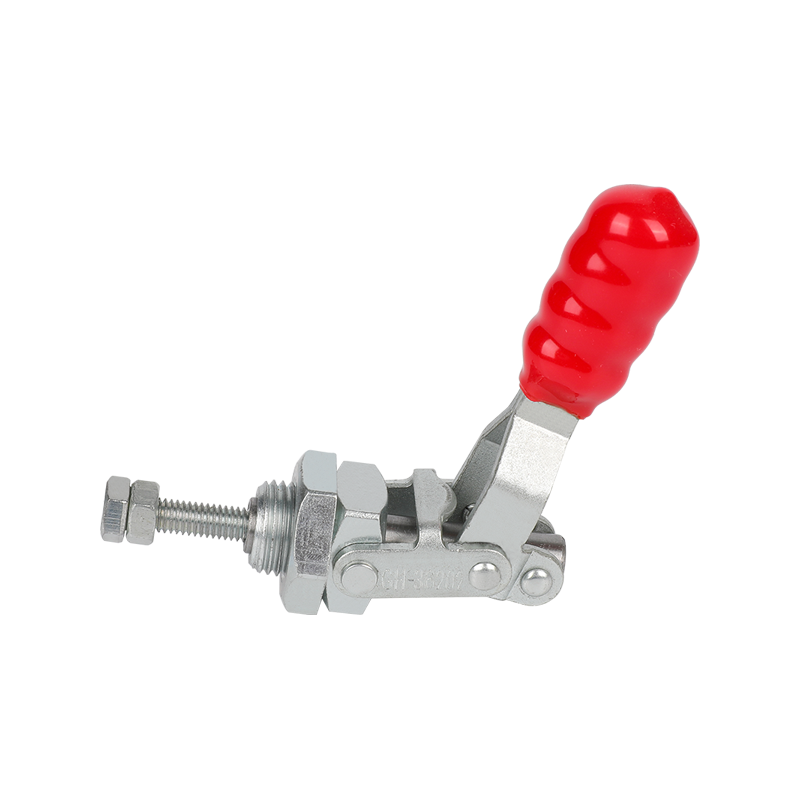

Open the clamp: Hold the handle of the clamp and gently pull it back to open the pressure head part of the clamp.

During the pulling process, pay attention to the angle and stroke of the handle movement to ensure that the clamp can be fully opened.

Check whether the pressure head part of the clamp is fully opened to clamp the workpiece smoothly.

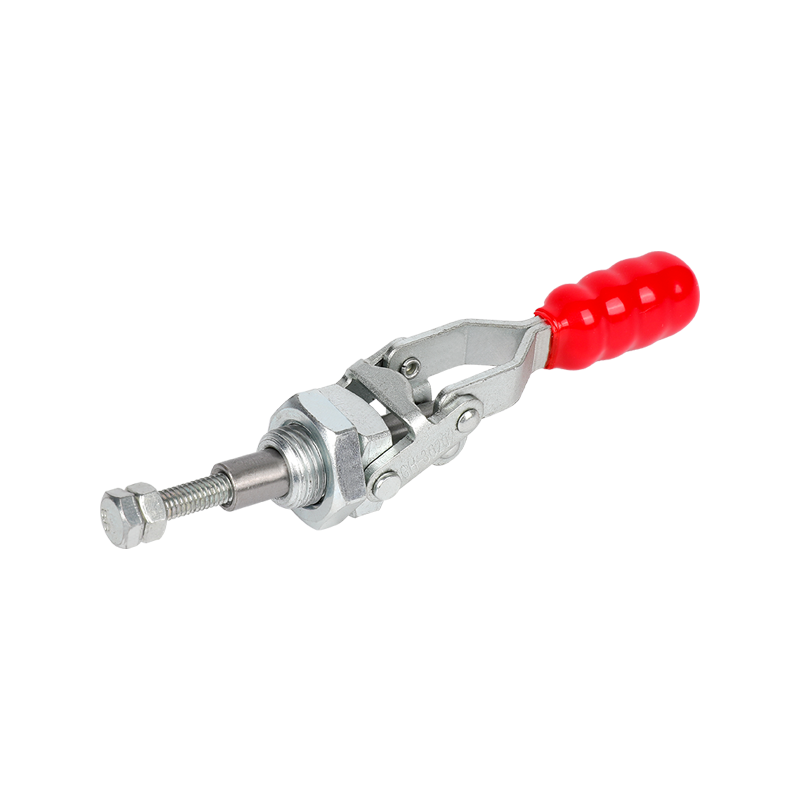

Clamp the workpiece: Place the workpiece on the pressure head part of the clamp to ensure that the contact surface between the workpiece and the clamp is flat and stable. Push the handle forward to close the pressure head part of the clamp and clamp the workpiece. During the pushing process, pay attention to the movement speed and strength of the handle to avoid damage to the workpiece or the clamp due to too fast or too strong. Check whether the workpiece has been firmly clamped. If necessary, fine-tune the position or clamping force of the clamp.

Locking the clamp (if the clamp has this function): After clamping the workpiece, if the clamp has a locking function, the locking mechanism can be rotated to lock the clamp in a closed state. The locking mechanism can ensure that the clamp will not accidentally loosen during operation, improving work safety.

Release the workpiece: When you need to release the workpiece, first unlock the locking mechanism (if the clamp has this function). Then hold the handle of the clamp and gently pull back to open the pressure head of the clamp.

When releasing the workpiece, you also need to pay attention to the speed and strength of the handle to avoid damage to the workpiece or the clamp due to too fast or too strong.

3. Precautions

Operation safety: When operating the Push pull toggle clamp, ensure the safety of the surrounding environment and avoid collisions with other equipment or personnel. At the same time, wear appropriate protective equipment, such as gloves, goggles, etc.

Clamping force control: When clamping the workpiece, the size of the clamping force should be reasonably controlled according to factors such as the material, shape and size of the workpiece. Avoid excessive clamping force that may damage the workpiece or the clamp, and also ensure that the clamping force is strong enough to prevent the workpiece from loosening or falling off during operation.

Regular maintenance: Regularly maintain and service the Push pull toggle clamp, such as cleaning, lubrication, tightening, etc. Ensure that all parts of the clamp are in good condition to extend the service life of the clamp.

English

English Español

Español русский

русский