-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

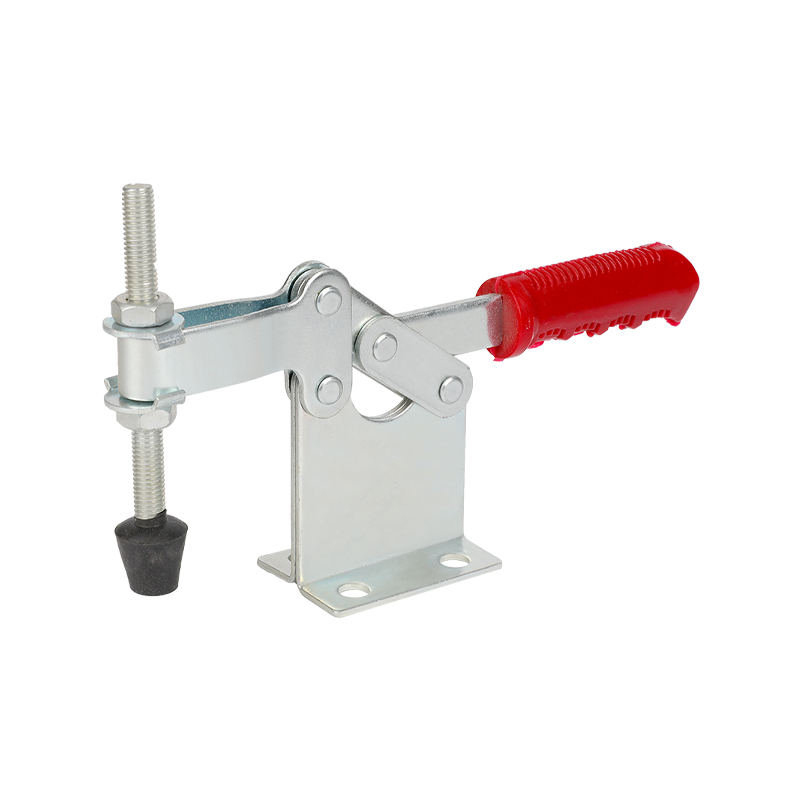

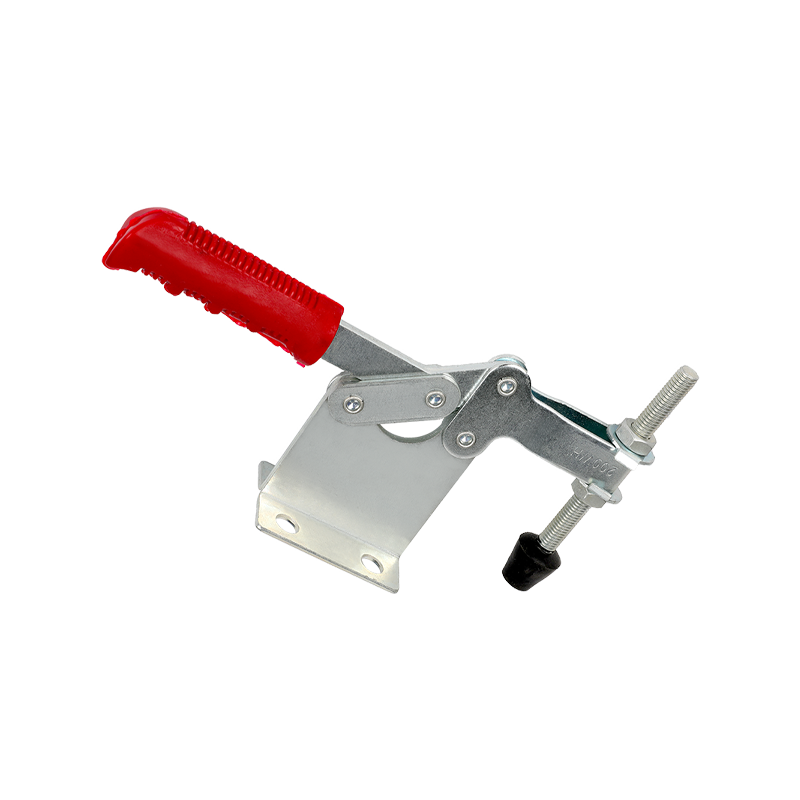

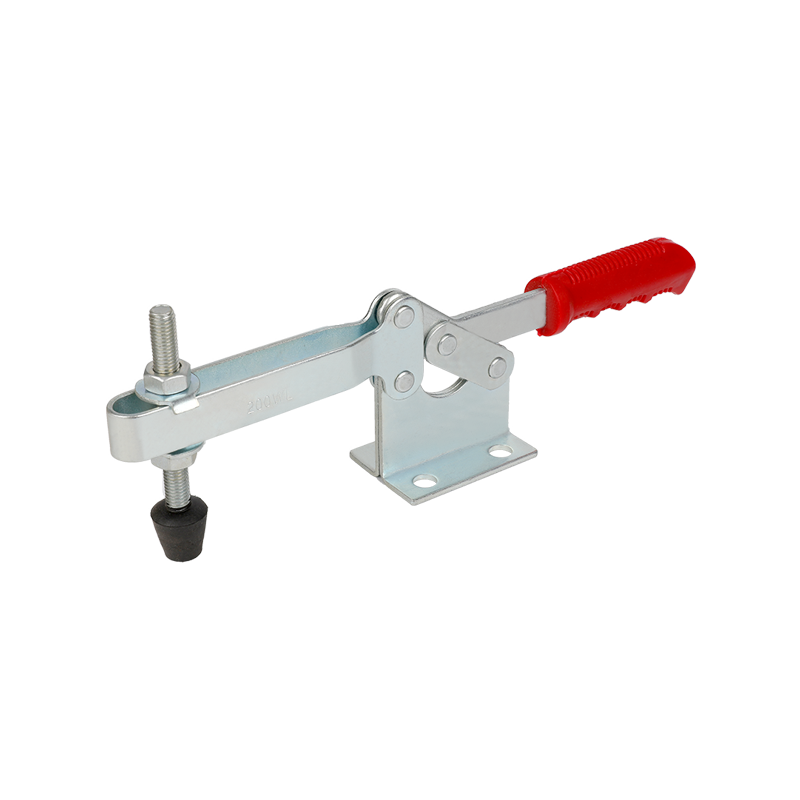

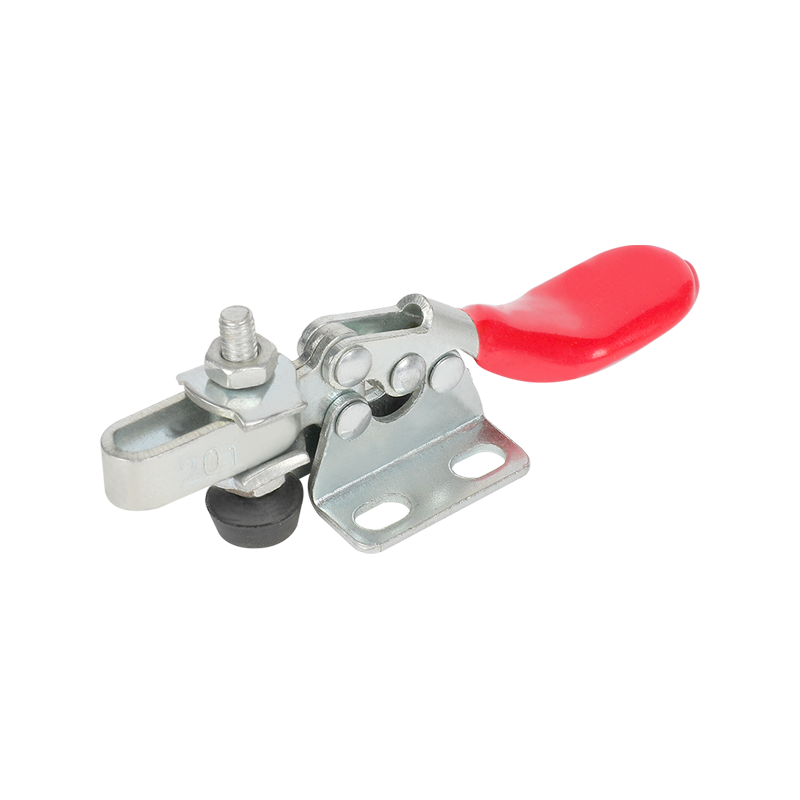

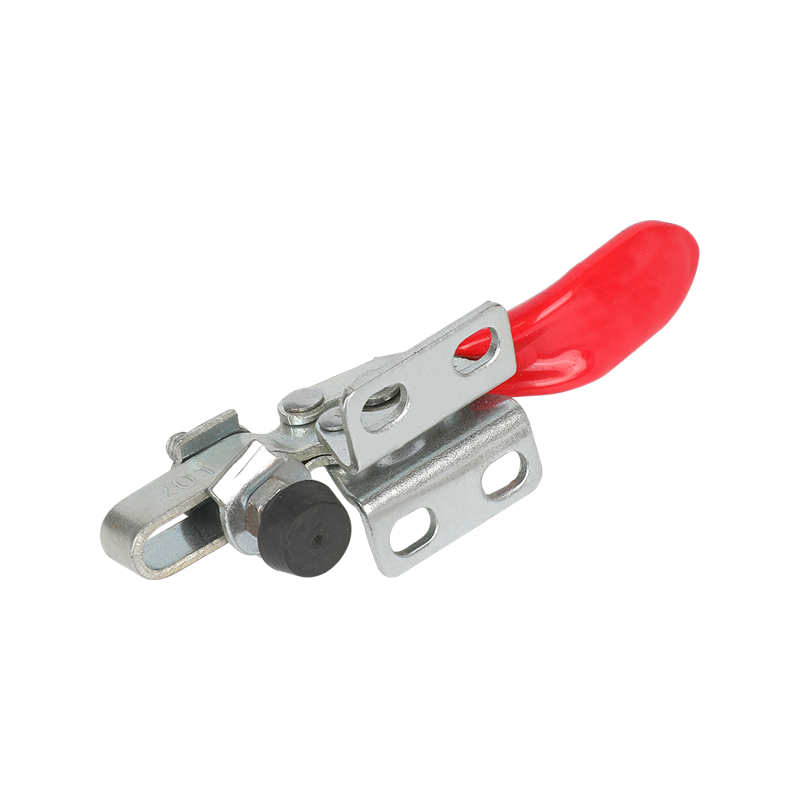

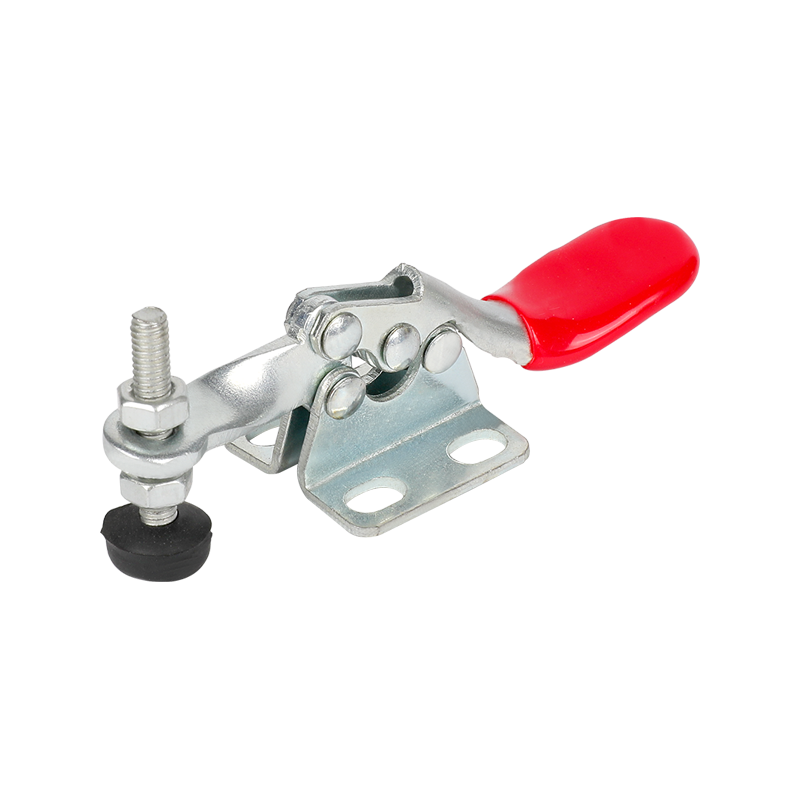

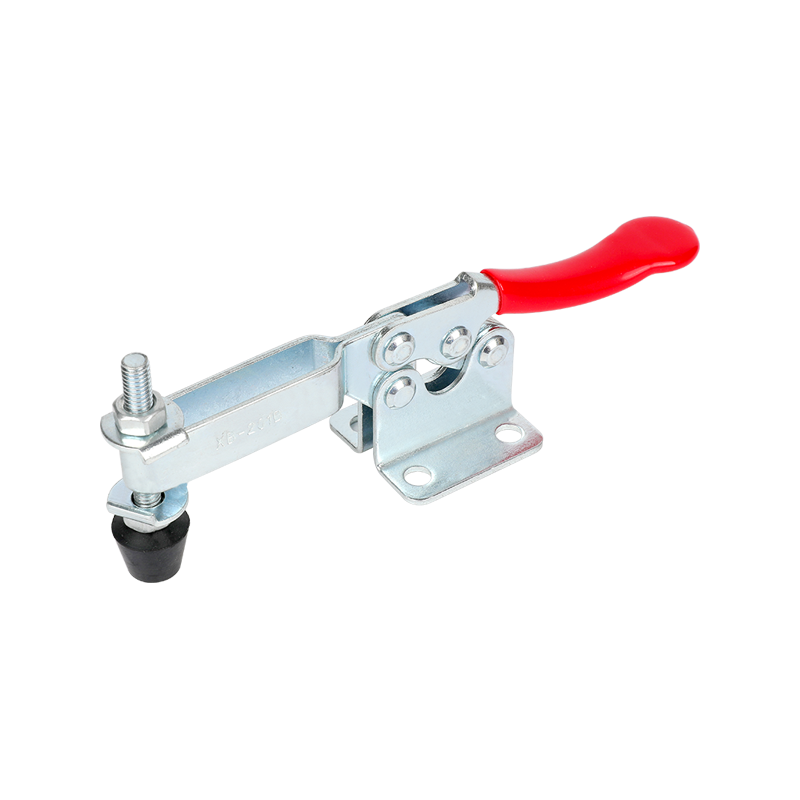

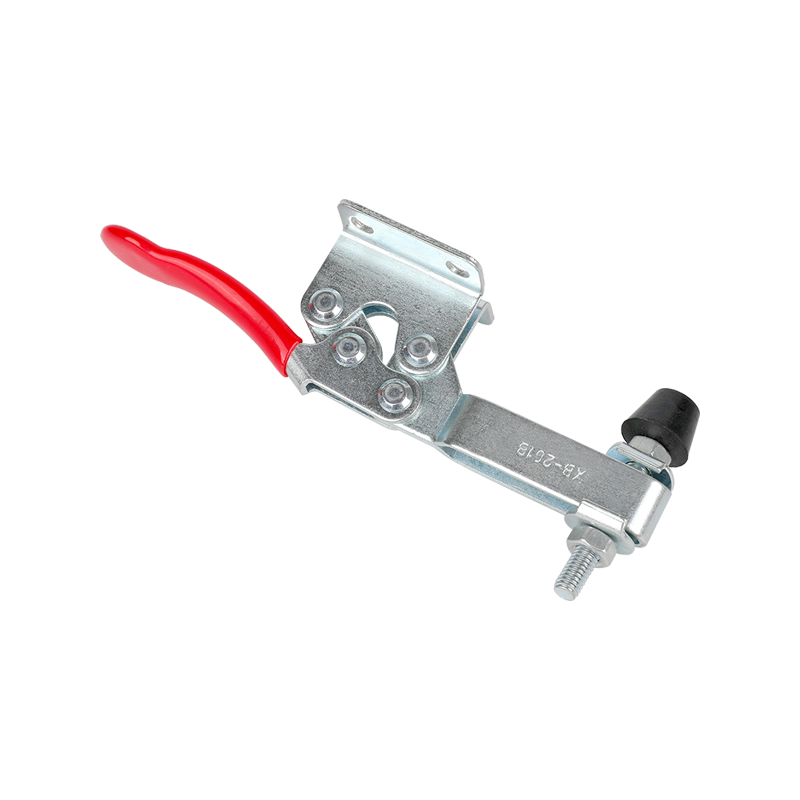

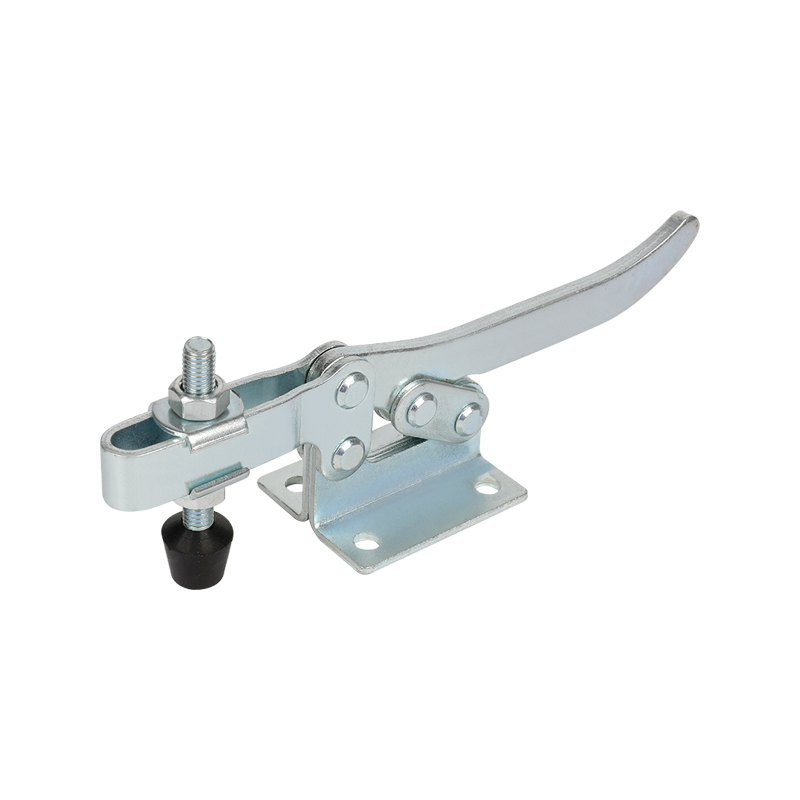

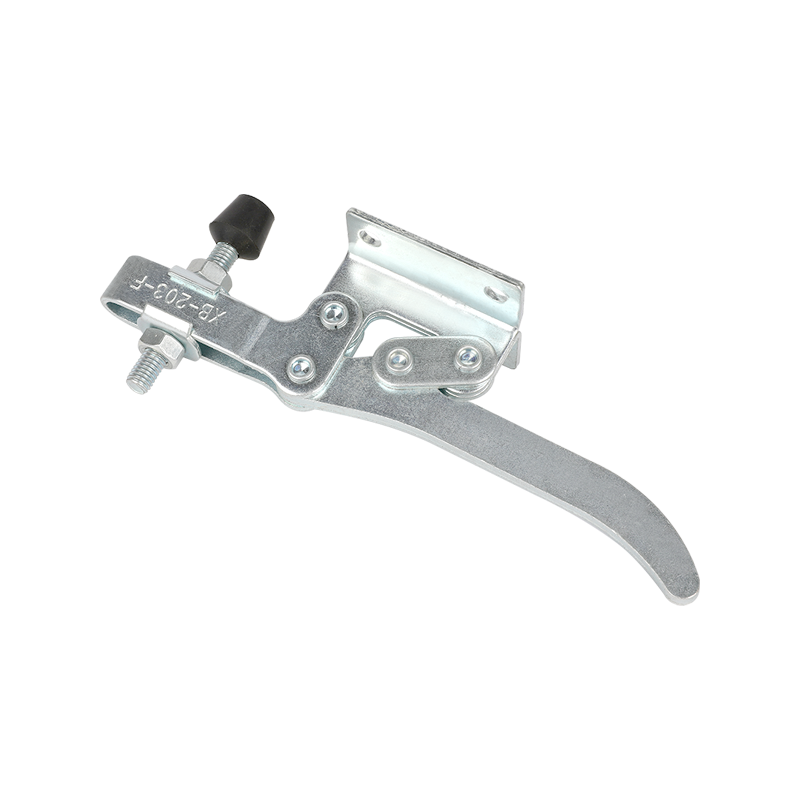

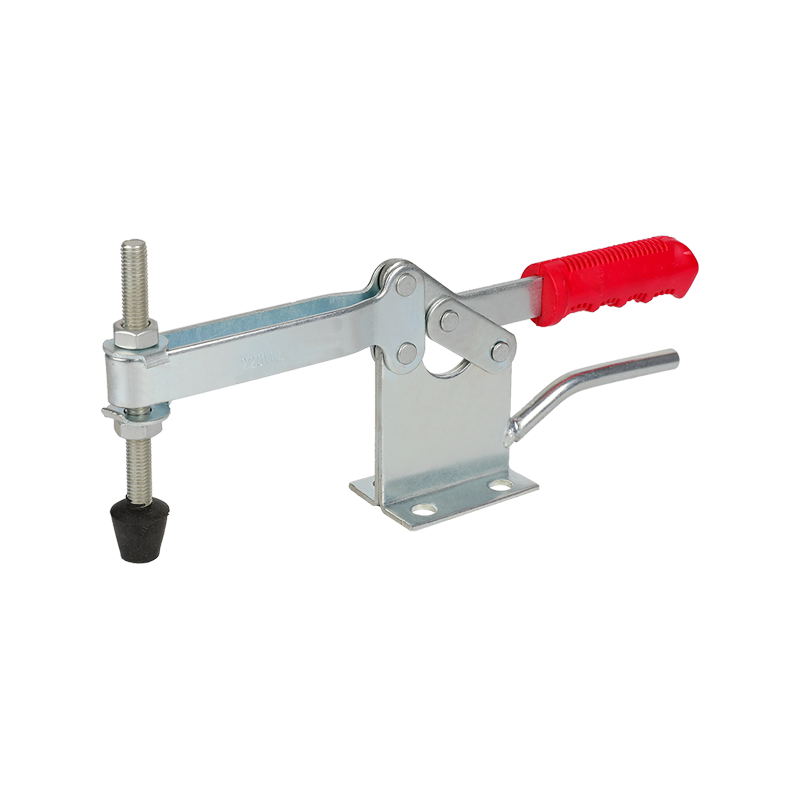

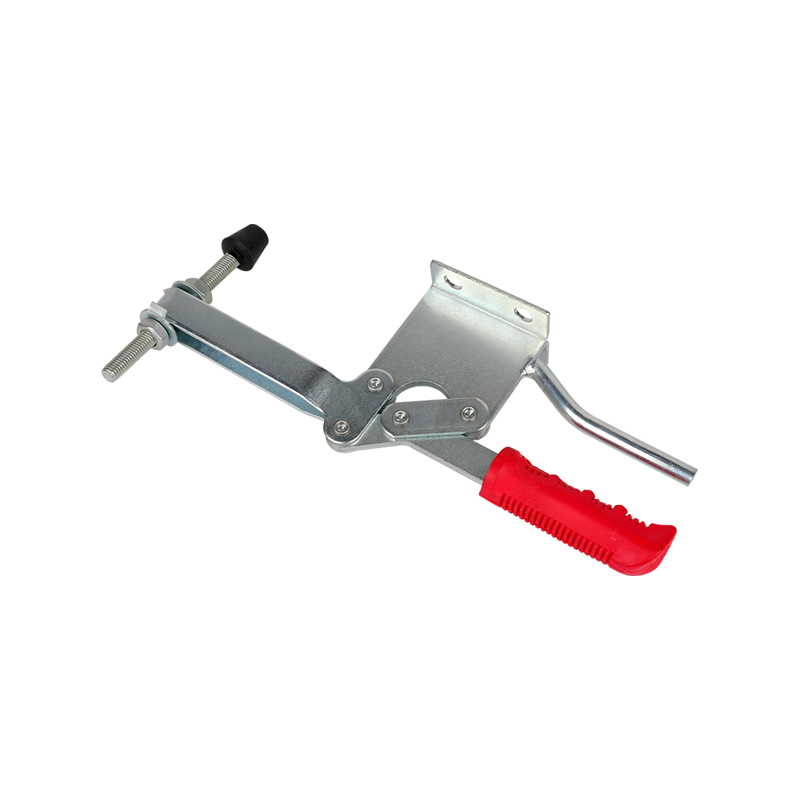

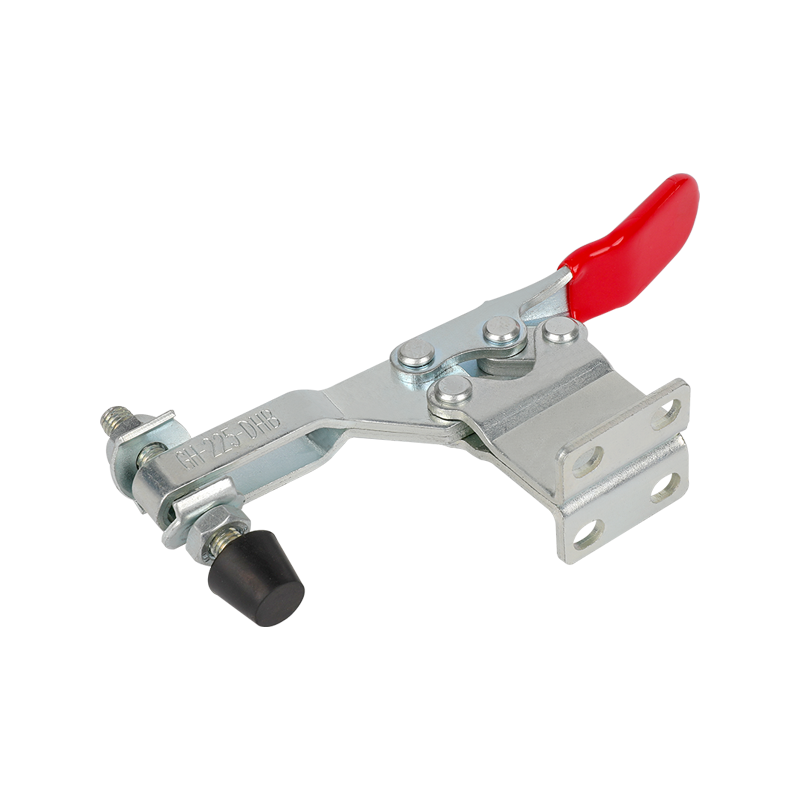

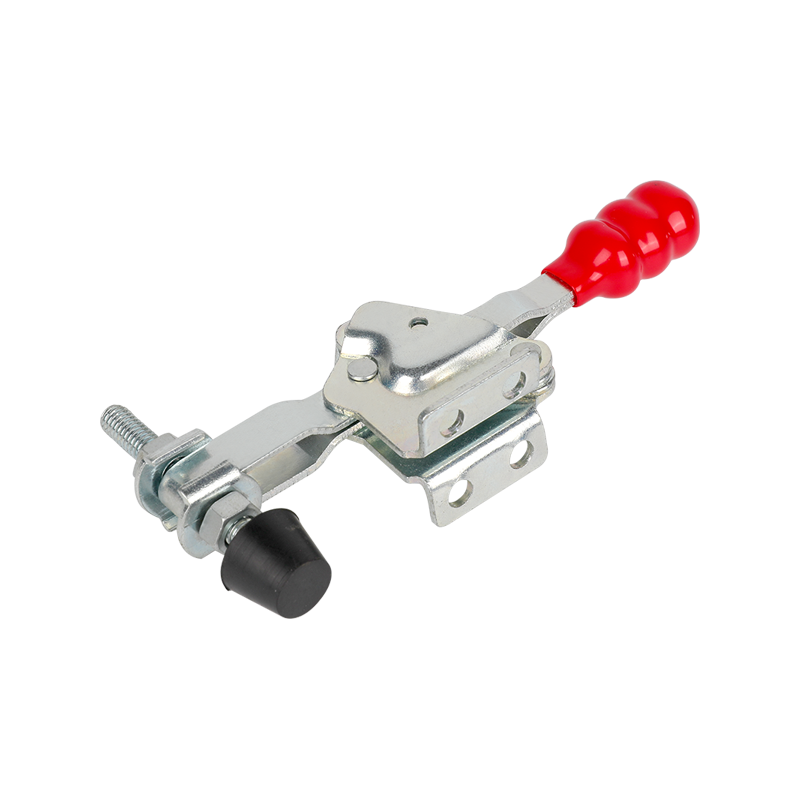

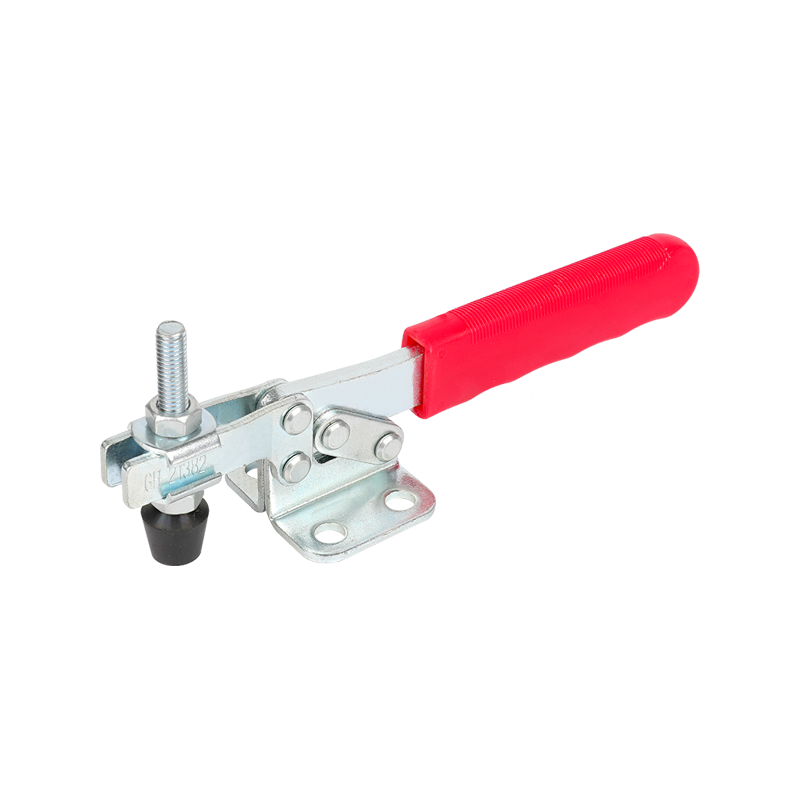

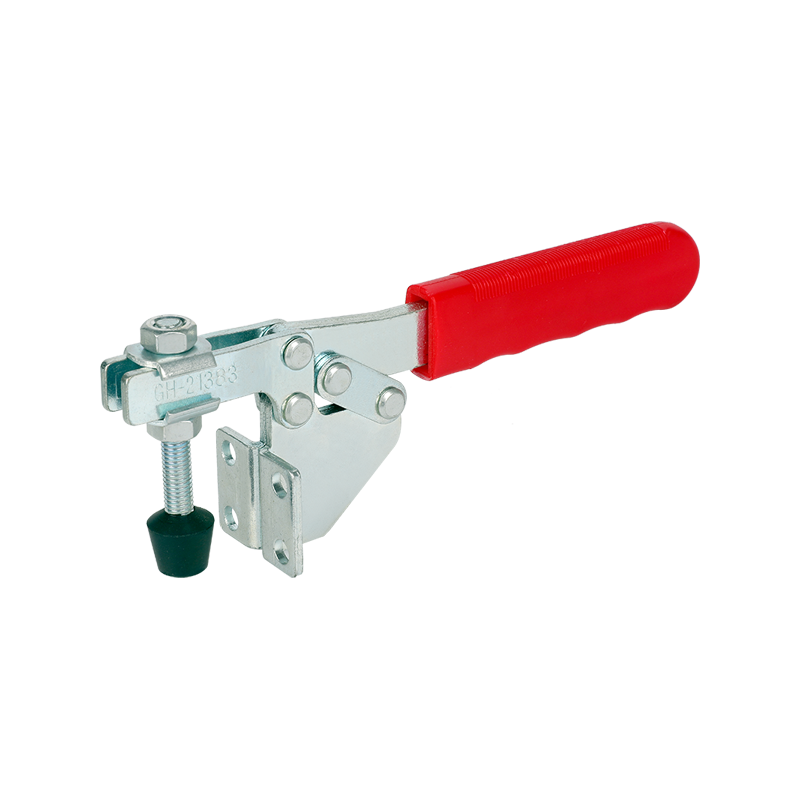

What are the advantages of Horizontal Toggle Clamp?

1. Reasonable structural design and convenient operation

The structural design of Horizontal Toggle Clamp enables it to quickly and effectively fix or release the workpiece in the horizontal direction. Horizontal Toggle Clamp uses the principle of lever, so that users only need to apply a small amount of force to generate a large clamping force through the linkage system. This design greatly improves the convenience and efficiency of operation. Due to the ingenious design of the linkage system, Horizontal Toggle Clamp can complete the clamping or release action in a very short time, which is especially important for production environments that require frequent workpiece replacement. Once the workpiece is clamped, the Horizontal Toggle Clamp can maintain a stable clamping force to ensure that the workpiece does not move or fall off during processing. This stability is essential to ensure processing accuracy and product quality. Horizontal Toggle Clamp usually has an adjustable clamping range to accommodate workpieces of different sizes and shapes. This flexibility enables the clamp to be widely used in various processing scenarios. In order to ensure the safety of operators, Horizontal Toggle Clamp is usually designed with a safety lock or locking mechanism to prevent the clamp from closing or opening suddenly in an uncontrolled manner.

2. Stable and reliable clamping force

The clamping force of the Horizontal Toggle Clamp is stable and reliable, and can maintain a stable fixation of the workpiece for a long time. Its clamping principle is to use the transmission action of the lever to make the two parts of the clamp quickly approach and clamp the workpiece, forming a strong clamping force. This clamping force is not only stable, but also can be adjusted as needed to meet the needs of different workpieces and processing.

3. Strong adaptability and wide application

The Horizontal Toggle Clamp has strong adaptability and can adapt to workpieces of different shapes, sizes and materials. Its clamp part is usually designed with multiple clamping ports of different sizes and shapes to meet the clamping needs of different workpieces. In addition, the clamp can also be used in conjunction with other auxiliary tools, such as positioning pins, pads, etc., to further improve the stability and accuracy of clamping. Due to its strong adaptability, the Horizontal Toggle Clamp has been widely used in woodworking, machinery manufacturing, mold manufacturing, automated production lines and other fields.

4. Strong durability and long service life

The Horizontal Toggle Clamp is usually made of high-quality materials, precision processed and heat treated, and has high durability and service life. Its compact structure, high strength, good impact resistance, and can maintain stable performance in harsh working environments. In addition, the maintenance of the clamp is relatively simple. It only needs to be cleaned and checked regularly for wear of each component, and the worn parts can be replaced in time to ensure its long-term stable operation.

5. High safety and low operating risk

The Horizontal Toggle Clamp takes safety factors into full consideration during the design and manufacturing process. Its easy operation, stable and reliable clamping force, and strong adaptability greatly reduce the operating risk. In addition, the clamp is also equipped with a variety of safety protection devices, such as overload protection and limit switches, to ensure that no damage is caused to workers and equipment during operation.

6. Improve production efficiency and reduce production costs

The use of the Horizontal Toggle Clamp can greatly improve production efficiency and reduce production costs. Its quick clamping and release function makes workpiece replacement and positioning faster, reducing downtime in the production process. At the same time, the stability and reliability of the clamp also ensure the smooth progress of the production process, reducing production accidents and quality problems caused by loose workpieces or clamp failures. In addition, due to its strong adaptability and versatility, the Horizontal Toggle Clamp can adapt to different workpieces and processing requirements, reducing equipment investment and replacement costs in the production process.

English

English Español

Español русский

русский