-

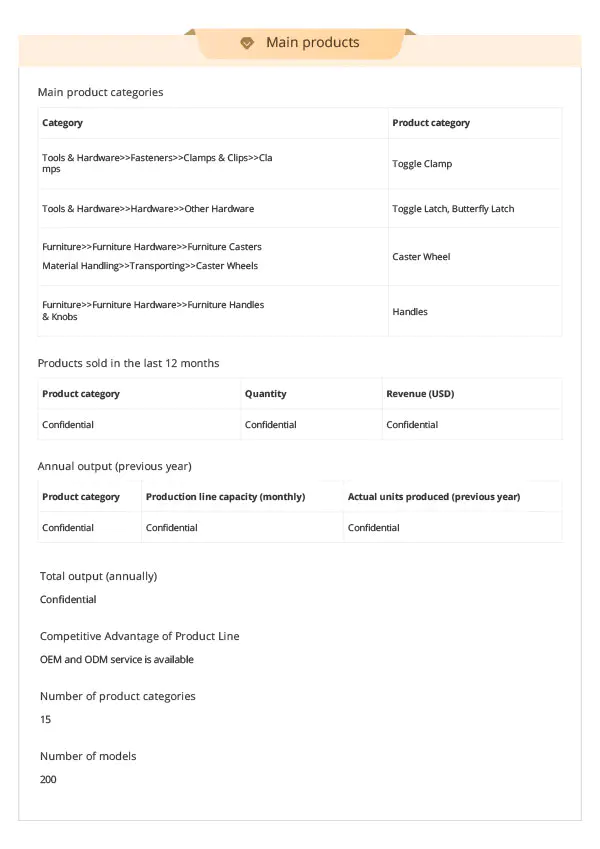

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

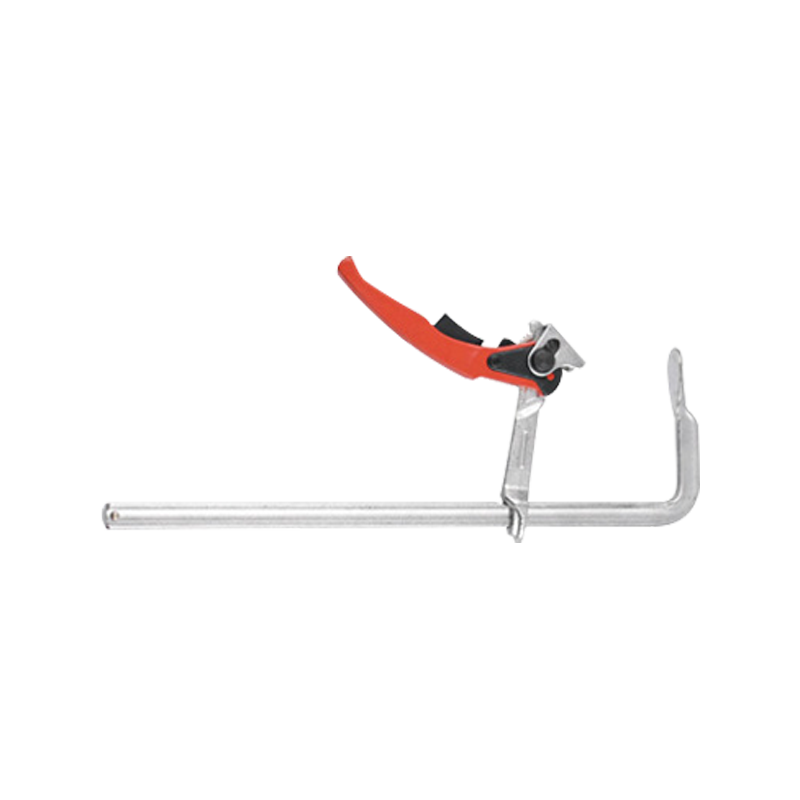

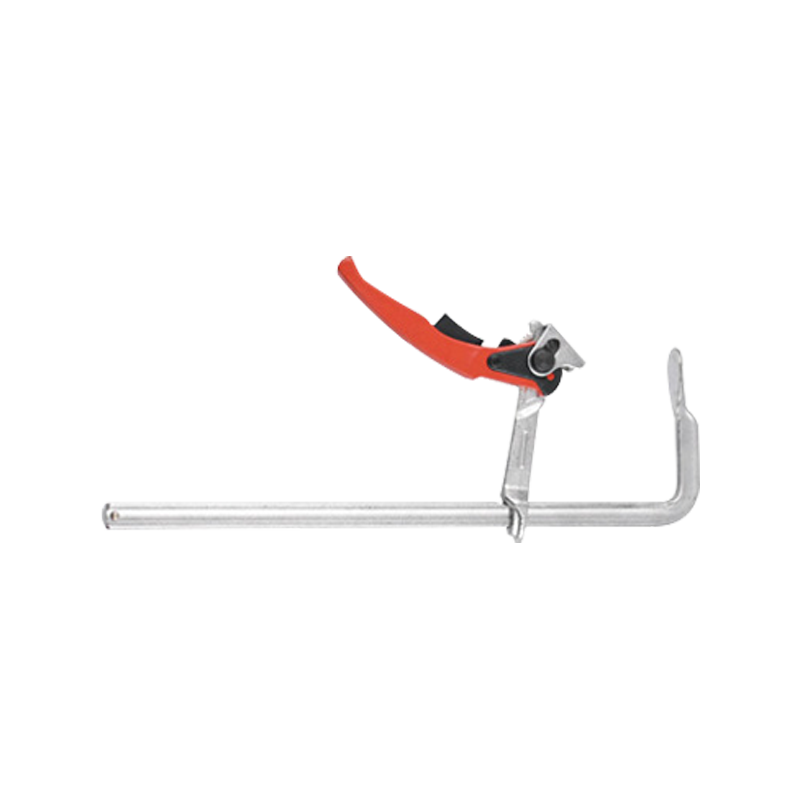

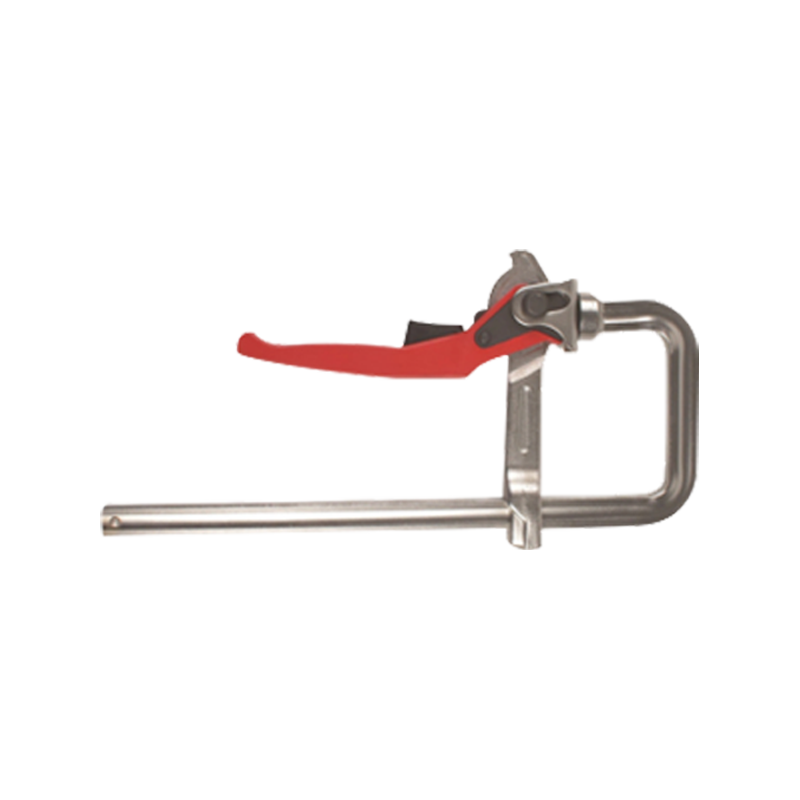

How to choose the right F-type toggle fixture for a specific application?

When choosing an F-type toggle fixture for a specific application, you can consider the following key factors:

1. Clamping force and clamping range: Make sure the clamping force of the F-type toggle fixture can meet the needs of the workpiece, and consider whether the clamping range is suitable for the size of the workpiece.

2. Workspace and installation requirements: According to the size and shape of the workspace, choose the appropriate F-type toggle fixture size and installation method to ensure that it can be easily used on existing equipment or workbenches.

3. Durability and material selection: Consider the durability and material selection of the F-type toggle fixture, especially whether it can withstand specific environmental conditions (such as high temperature, chemicals), and whether it will not deform or damage after long-term use.

4. Accuracy and repeatability: For applications that require precise positioning and repeated use, choose an F-type toggle fixture with good accuracy and stability to ensure the accuracy and stability of workpiece positioning.

5. Operational convenience and safety: Consider the convenience of operation of the F-type switching fixture, such as whether the design of the operating handle or button conforms to the operator's usage habits and ensures safety during use.

6. Adapt to diverse needs: If there are many different workpiece sizes or shapes to be processed, consider choosing an F-type switching fixture that can adapt to diverse needs, or consider equipping multiple fixtures of different specifications to meet different work requirements.

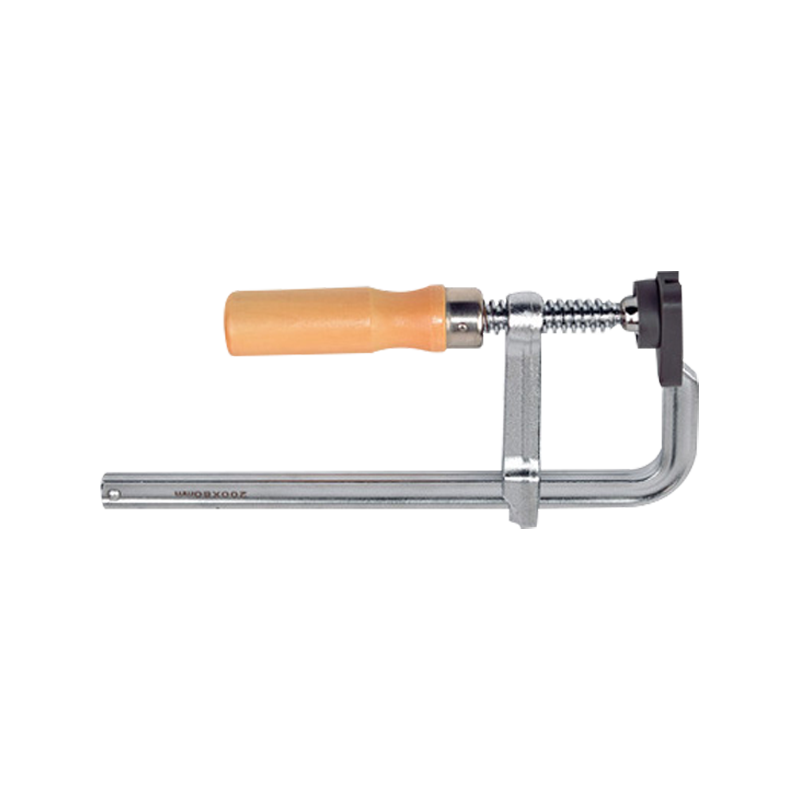

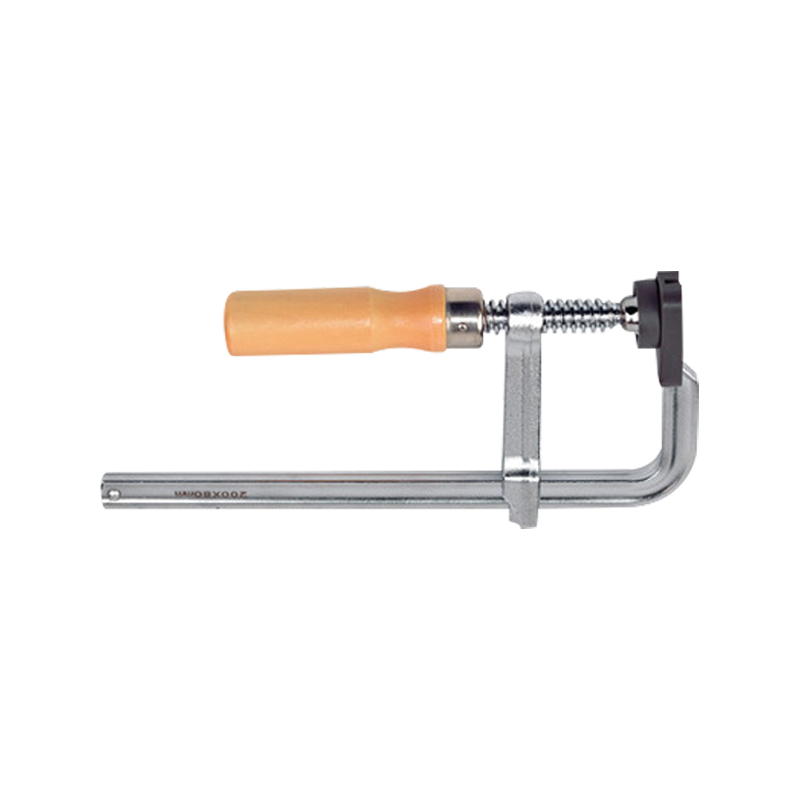

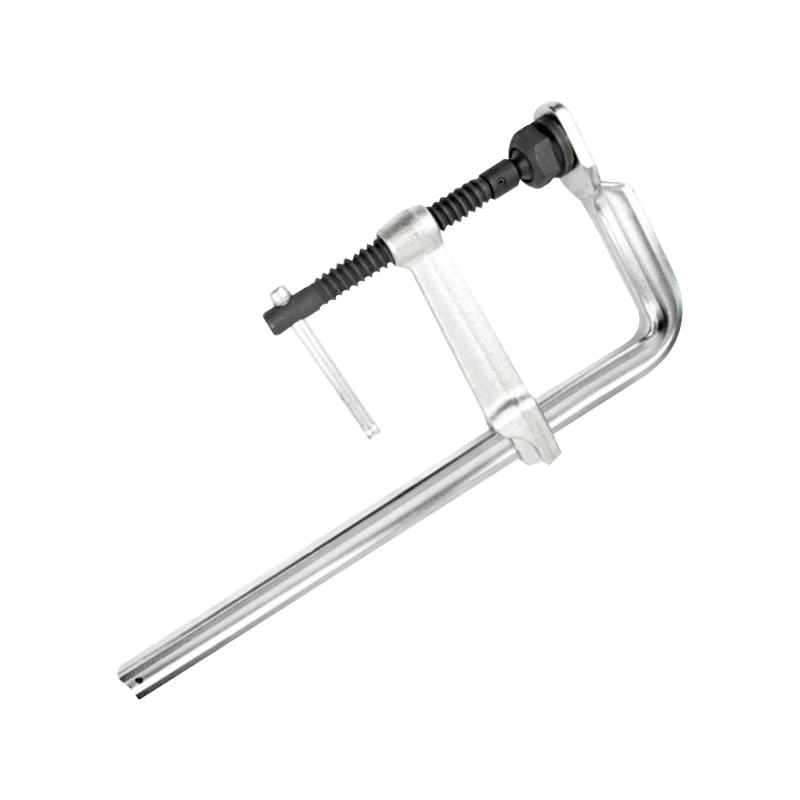

In which industries are F-type switching fixtures most common or widely used?

F-type switching fixtures are widely used in the following industries:

1. Metalworking and machinery manufacturing industry: In metalworking processes, F-type switching fixtures are often used to clamp workpieces to ensure processing accuracy and safety. In machinery manufacturing, they are used to clamp mechanical parts for assembly or processing.

2. Woodworking and furniture manufacturing industry: In woodworking and furniture manufacturing, F-type switching fixtures are widely used to clamp and position wood, boards or furniture parts to ensure assembly and processing accuracy.

3. Plastic processing industry: In the production of plastic products, F-type switching fixtures are used to clamp and fix plastic molds or parts for injection molding or other plastic processing processes.

4. Electronic and electrical manufacturing industry: In the assembly process of electronic equipment, F-type switching fixtures help clamp and fix small electronic components to ensure accurate assembly and connection.

5. Automotive and Aerospace Industry: In automotive and aerospace manufacturing, F-type toggle clamps are used to clamp and position vehicle parts or aircraft components, ensuring high-precision assembly and safety.

English

English Español

Español русский

русский