-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

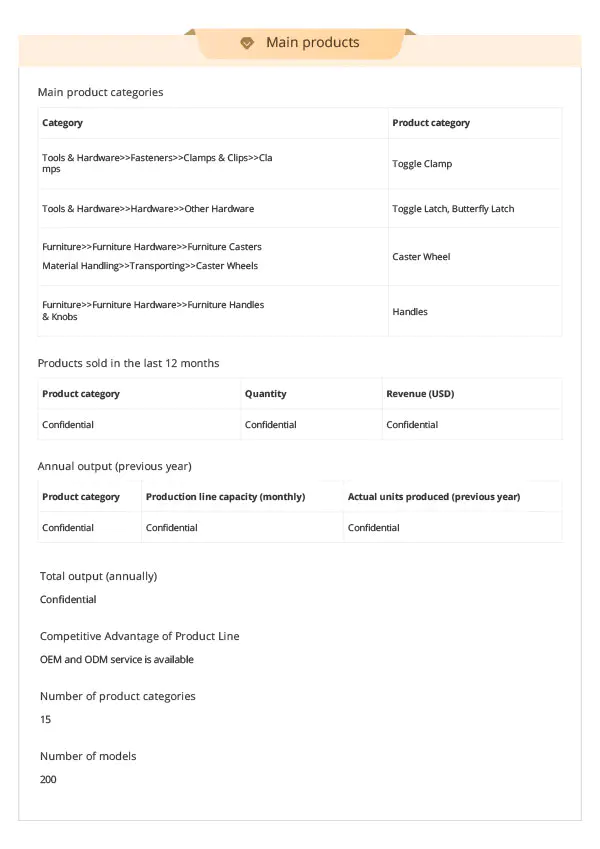

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

What are the main uses of C-type toggle clamps?

The main uses of C-type toggle clamps include the following aspects:

Fix and clamp: C-type toggle clamps are often used to fix and clamp workpieces, especially in situations where quick clamping and release are required, such as assembly lines, clamping operations in processing technology, etc.

Tool clamping: In the manufacturing and processing process, C-type toggle clamps are widely used as part of tooling fixtures to ensure the stability and accuracy of workpieces.

Mold clamping: In the process of mold manufacturing and use, C-type toggle clamps are used to clamp molds to ensure safety and stability during mold operation.

Positioning and pressing: Used for positioning and pressing operations of workpieces, such as aligning and pressing parts into position on an assembly line.

Replacing traditional fixtures: It can replace traditional mechanical fixtures or fixture systems, especially in situations where space is limited or quick adjustment is required, C-type toggle clamps perform well.

C-type clamps are widely used in industrial production lines, mechanical processing, mold manufacturing and other fields with their simple and efficient design, providing convenient and reliable clamping solutions for process operations.

In which industries are C-type toggle clamps common?

C-type toggle clamps are very common in many different industries, mainly including the following fields:

Manufacturing: In the manufacturing industry, especially in the fields of metal processing, plastic processing and woodworking, C-type toggle clamps are often used to clamp workpieces, fix molds, and perform assembly and positioning operations.

Mold manufacturing: In the mold manufacturing process, C-type toggle clamps are widely used to clamp and stabilize molds to ensure the accuracy and safety of molds during processing and use.

Electronic and electrical equipment manufacturing: In the assembly process of electronic equipment and electrical equipment, C-type toggle clamps are often used to clamp and position small parts to ensure the accuracy and quality of assembly.

Automobile manufacturing and repair: In the automobile manufacturing process, C-type toggle clamps can be used to clamp and fix vehicle components, such as assembly and positioning operations of parts. In automobile repair workshops, they are also often used for temporary clamping and fixing work.

Aerospace: In the aerospace field, C-type toggle clamps are often used to assemble aircraft parts and clamp components of aviation equipment.

Medical Device Manufacturing: C-type clamps are used to clamp and position various medical device components during the manufacturing and assembly of medical devices.

Furniture Manufacturing: In the furniture manufacturing industry, C-type clamps are often used to clamp and position furniture parts to ensure accuracy and stability during assembly.

C-type clamps are suitable for various industrial applications that require clamping, positioning and pressing operations due to their simple and reliable clamping function.

English

English Español

Español русский

русский