-

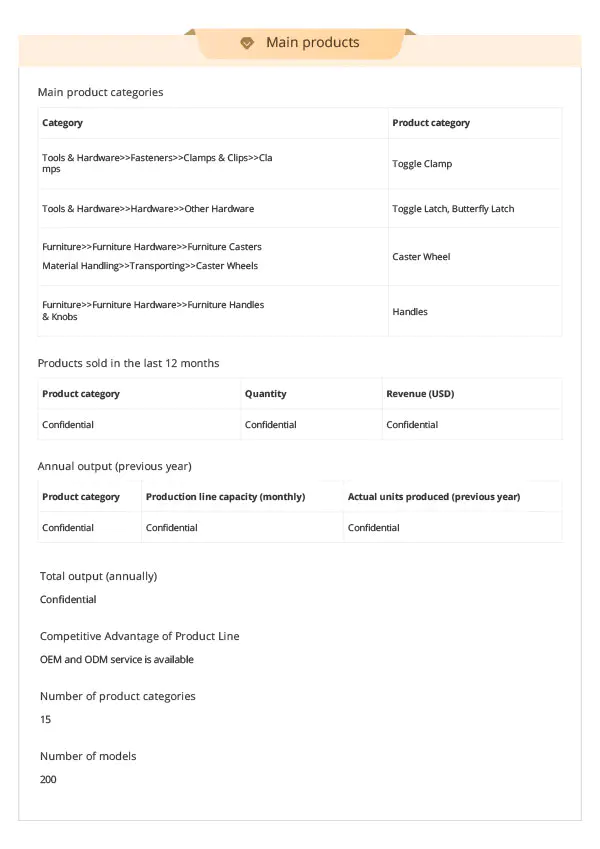

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

When Rotomolding Box Pre-buried parts are used to manufacture amusement facilities in the entertainment industry, do we need to consider their protection of human safety?

When rotomolding box embedded parts are used to manufacture amusement facilities in the entertainment industry, we do need to fully consider their protection of human safety.

Material safety: Rotomolding Box Pre-buried parts should be made of non-toxic, odorless materials that meet relevant safety standards. This material will not produce harmful substances during the manufacturing process, nor will it release harmful substances during use, ensuring that human health is not harmed.

Structural design safety: The design of amusement facilities needs to meet relevant safety specifications and standards to ensure that the structure is stable and firm. As an important part of amusement facilities, the design of rotomolding box embedded parts also needs to meet these requirements. At the same time, when the Rotomolding Box Pre-buried parts are embedded in the amusement facilities, it is necessary to ensure that they are closely integrated with other parts of the facilities to prevent safety accidents caused by loosening or falling off.

Installation and maintenance safety: The installation of Rotomolding Box Pre-buried parts needs to be carried out by professionals to ensure that the installation position and quantity are accurate and firmly fixed. During use, regular inspections and maintenance are required to ensure that they are in good condition and without damage. Damaged or aged Rotomolding Box Pre-buried parts need to be replaced in time to avoid safety accidents.

Ergonomic considerations: When manufacturing amusement facilities, it is necessary to consider the principles of ergonomics to ensure that the use of the facilities conforms to the physiological and psychological characteristics of the human body. As part of the facility, the Rotomolding Box Pre-buried parts also need to consider these factors, such as the size, shape, and material of the facility, which need to meet the requirements of human comfort and safety.

When Rotomolding Box Pre-buried parts are used to manufacture amusement facilities in the entertainment industry, their protection of human safety needs to be fully considered. By selecting safe materials, designing reasonable structures, carrying out professional installation and maintenance, and considering the principles of ergonomics, the safety and reliability of amusement facilities can be ensured, providing tourists with a safe and enjoyable play experience.

Why can Rotomolding Box Pre-buried parts improve the stability and load-bearing capacity of buildings in the construction industry?

Rotomolding Box Pre-buried parts can improve the stability and load-bearing capacity of buildings in the construction industry, mainly due to their unique materials and design characteristics, as well as precise installation and application methods.

Rotomolding Box Pre-buried parts are usually made of high-strength, corrosion-resistant rotomolding materials, which have good mechanical properties and durability, can withstand large loads and maintain long-term stability. Compared with traditional embedded parts, Rotomolding Box Pre-buried parts have higher strength and rigidity, and can maintain structural integrity and stability when bearing external loads.

Rotomolding Box Pre-buried parts can be customized according to the specific needs and structural characteristics of the building during the design and manufacturing process. By pre-embedding Rotomolding Box Pre-buried parts in key parts such as the foundation, beams, columns, and plates of the building, it can be ensured that these parts have higher strength and stability when bearing loads. At the same time, the installation position and quantity of rotomolding box embedded parts can also be accurately calculated and controlled according to the design requirements of the building to achieve the best load-bearing effect.

The pre-positioning method is used in the installation process of the Rotomolding Box Pre-buried parts, that is, a reserved cavity is set in the template before the concrete is poured, and the Rotomolding Box Pre-buried parts are embedded in the cavity. This method can ensure that the embedded parts are tightly combined with the concrete to form a whole, thereby improving the overall stability and load-bearing capacity of the building.

Rotomolding Box Pre-buried parts can improve the stability and load-bearing capacity of buildings in the construction industry, mainly due to their high strength, corrosion-resistant material properties, precise design and manufacturing process, and precise installation and application methods. These advantages make Rotomolding Box Pre-buried parts an indispensable part of modern buildings.

English

English Español

Español русский

русский