-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

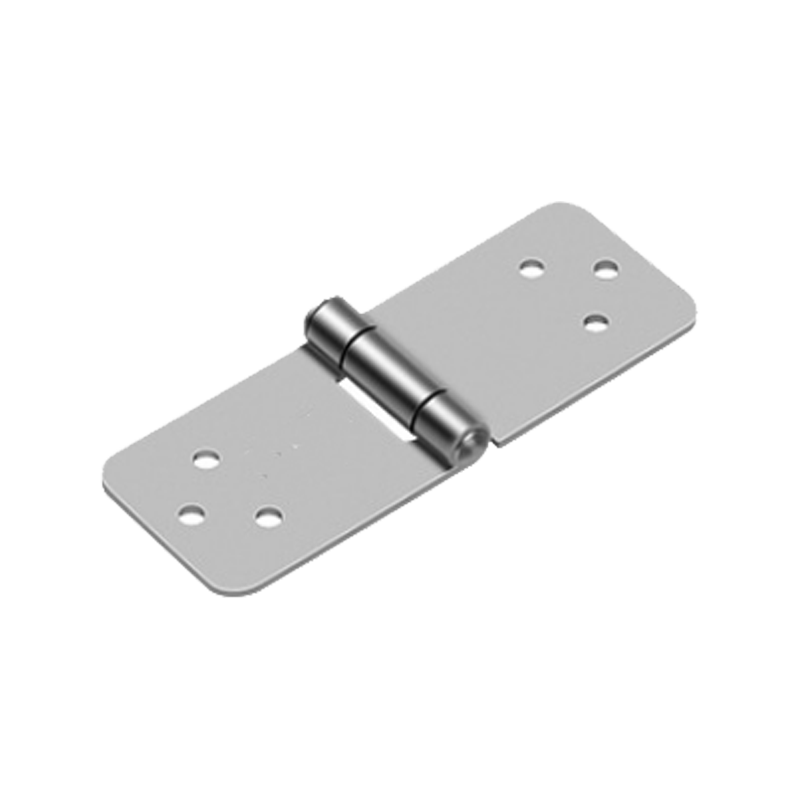

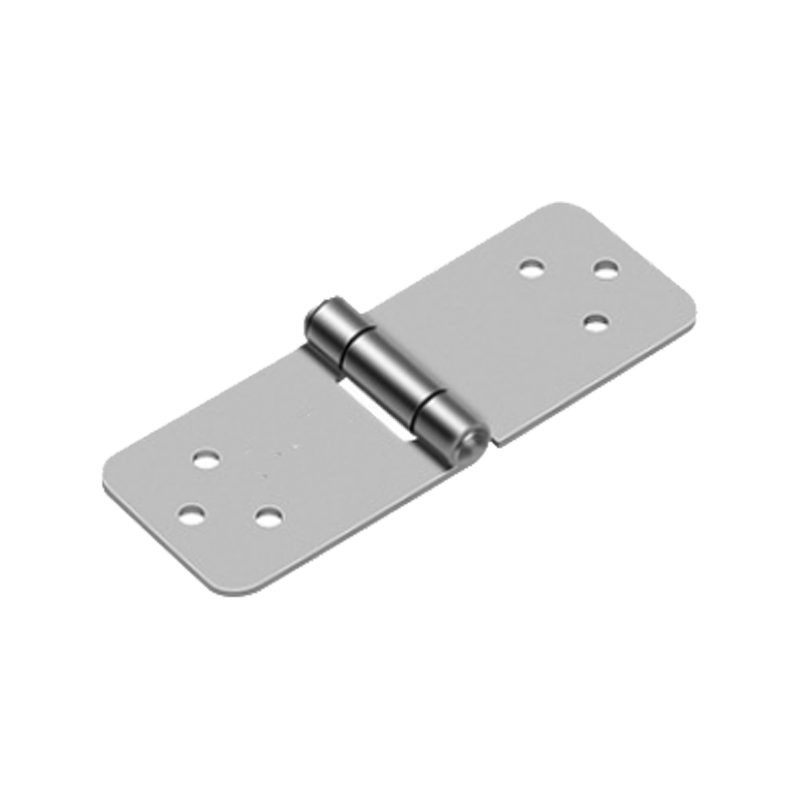

How to balance the load-bearing capacity and weight of the rotomolding box hinge during the design process?

In the process of designing the rotomolding box hinge, it is crucial to balance the load-bearing capacity and weight. Here are some key steps to balance these two considerations:

Material selection:

Give priority to materials with high strength but low weight, such as high-strength aluminum alloys or composite materials, to ensure that the weight is reduced under the same load-bearing capacity.

According to the specific application environment and requirements of the hinge, select materials with good corrosion resistance and durability to ensure the stability of performance under long-term use.

Structural design:

By optimizing the structural design of the hinge, such as adopting a reasonable transmission mechanism and reducing unnecessary structural parts, the overall weight can be reduced while ensuring sufficient load-bearing capacity.

When designing, the stress distribution and transmission path when the rotomolding box is fully loaded should be fully considered to ensure that the hinge can be evenly stressed when bearing weight and avoid local overload.

Simulation and testing:

Use simulation tools such as finite element analysis (FEA) to simulate and analyze the hinge to predict its load-bearing capacity and deformation so that it can be optimized in the design stage.

Conduct actual tests, such as static load tests, impact tests, etc., to verify the bearing capacity and durability of the hinge, and make necessary adjustments and improvements based on the test results.

Determination of the balance point:

Determine the balance point of the hinge bearing capacity and weight according to specific needs and application scenarios. On the premise of ensuring sufficient bearing capacity, reduce the weight of the hinge as much as possible to achieve better performance and cost-effectiveness.

Through the above steps, the bearing capacity and weight of the rotomolding box hinge can be effectively balanced during the design process.

For rotomolding boxes of different sizes, how does adjusting the design of the rotomolding box hinge affect the performance of the hinge?

For rotomolding boxes of different sizes, adjusting the design of the rotomolding box hinge will directly affect the performance of the hinge, which is mainly reflected in the following aspects:

Adaptation of load-bearing capacity:

As the size of the rotomolding box increases, the weight it needs to bear will also increase accordingly. Therefore, when adjusting the design of the hinge, it is necessary to ensure that the load-bearing capacity of the hinge can match the weight of the rotomolding box. For example, a large rotomolding box may require a larger hinge or a combination of multiple hinges to improve the overall load-bearing capacity.

Enhancement of structural stability:

Rotomolding boxes of different sizes have different requirements for the structural stability of the hinge. Larger rotomolding boxes will generate greater torque when fully loaded, which requires the hinge to have stronger stability in structural design. By increasing the support points and optimizing the transmission structure, the structural stability of the hinge can be enhanced, thereby ensuring the stability and safety of the rotomolding box during opening and closing.

Ease of installation and use:

Rotomolding boxes of different sizes also have different requirements for the installation position and angle of the hinge when installing and using them. When adjusting the design of the hinge, it is necessary to consider the specific size and usage scenarios of the roto-molded box to ensure that the hinge is installed in a reasonable position and is easy to use. For example, for large roto-molded boxes, it may be necessary to design a longer hinge arm to facilitate the operator's operation.

Durability and life:

The size changes of the roto-molded box will also affect the durability and life of the hinge. Proper design can ensure that the hinge maintains good performance during long-term use. For example, by selecting high-strength, wear-resistant materials and reasonable structural design, the service life of the hinge can be extended.

Adjusting the design of the roto-molded box hinge to adapt to roto-molded boxes of different sizes is the key to ensuring the performance of the hinge. Through reasonable load-bearing capacity adaptation, enhanced structural stability, improved installation and use convenience, and guaranteed durability and life, the roto-molded box hinge can be ensured to perform at its best in actual applications.

English

English Español

Español русский

русский