-

2010

Founded In 2010

-

15,000m²

15000m ² Advanced Factory Building

-

2,800,000

Annual Shipment Volume Of 2800000 Packages

-

43+

43 Factory Employees

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

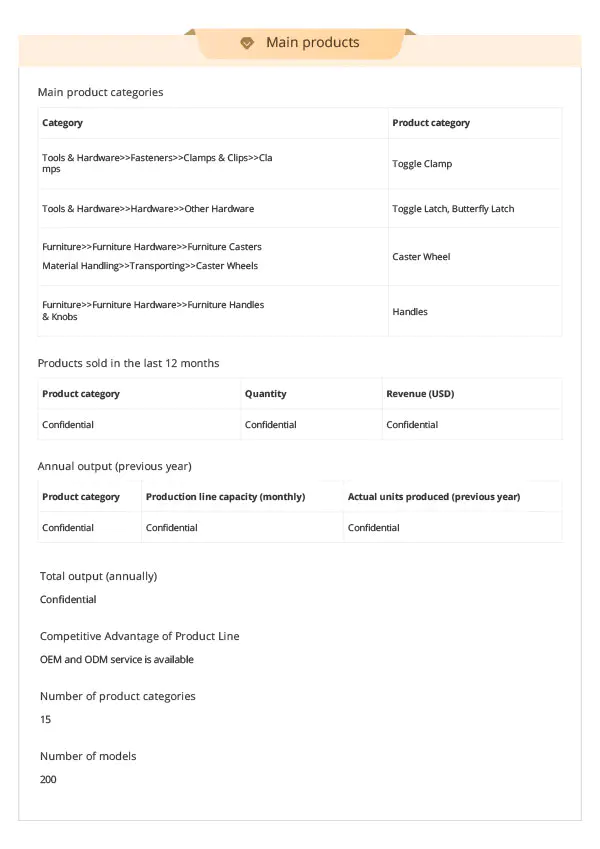

1. Material composition: A variety of steels give diverse performances The main material of Steel J...

READ MORE -

Assembly process of rivet quick lock puller The assembly of Rivet Quick Latch Buckle Puller Latch...

READ MORE -

1. Strictly follow the assembly criteria of design requirements The assembly of the horizontal togg...

READ MORE -

Sturdy engineering plastic lightweight arm: the perfect combination of strength and lightness The...

READ MORE -

As a common carbon structural steel, A3 steel has certain advantages in strength, plasticity and we...

READ MORE

For users with different hand shapes or strengths, does the handle design of the hardware flightcase handle supplier provide sufficient comfort and ease of use?

Variety: There are many types of hardware flightcase handles, such as cover ring handles, spring handles, box ring handles, and telescopic handles. This diversity means that the supplier may provide handle designs for different needs, thereby increasing its comfort and ease of use.

Adapt to different strengths: The design of the handle, especially the spring handle, usually has sufficient elasticity and tension to adapt to users with different strengths. The spring can make the pull ring rebound automatically, thereby enhancing the tension of the handle to meet the needs of different users.

Anti-slip hand guard design: Some handles have rubber rings on the pull ring. This design has an anti-slip hand guard function, which can prevent the box from slipping and falling off and rubbing the palm during dragging, thereby improving the comfort and safety of use.

Consideration of installation position: The handle can be installed on the left and right ends of the box body to facilitate users to drag and move; it can also be installed on the upper end of the box body to facilitate users to lift and move. This design flexibility allows users to choose the appropriate operation method according to their own habits and needs.

Surface treatment process: Hardware flight case handle suppliers usually perform surface treatment on the handles, such as electroplating, chrome plating, zinc plating, environmentally friendly zinc, nickel plating, etc., to enhance their durability and aesthetics. At the same time, the surface treatment process of stainless steel handles, such as vibration polishing, mirror polishing, sandblasting, etc., can also provide a comfortable touch.

What is the surface treatment process of the hardware flight case handles produced by the hardware flightcase handle manufacturer?

Electroplating process:

Definition: The electroplating process is currently the most widely used handle surface treatment process. It uses a battery containing metal ions in the electrolyte, and deposits metal ions on the surface of the substrate through electrolysis to form a metal coating.

Advantages: Strong controllability during processing, uniform and beautiful coating.

Disadvantages: Low corrosion resistance, the coating may crack, fall off and other problems.

Application: The electroplating process is suitable for metal products with durability requirements, such as handles made of stainless steel or alloy.

Spraying process:

Definition: Spraying process is to spray the pigment onto the surface of the substrate and then add appropriate thickeners, desiccants, diluents, etc. to solidify it.

Advantages: simple process, low cost, rich colors.

Disadvantages: corrosion resistance is not as good as electroplating process.

Application: Spraying process is suitable for surface treatment of substrates such as plastics and wood, but when used on hardware flight case handles, factors such as the pigments used and environmental protection need to be considered.

Painting process:

Definition: The painting process is to apply the colored paint on the surface of the substrate and then dry it at high temperature to form a solid color layer.

Features: not easy to fall off, strong scratch resistance, not easy to change color.

Disadvantages: high cost investment and long production cycle.

Application: The painting process is suitable for handle products that require high surface treatment, especially home decoration handles that require beauty, comfort and durability.

Other processes:

Hot-dip galvanizing: by immersing the handle in a molten zinc plating tank at about 510℃, a layer of passivated zinc covering is formed on its surface to improve corrosion resistance.

Mechanical plating: The coating is cold-welded to the surface of the standard product by impacting the surface of the product with particles of the plated metal.

English

English Español

Español русский

русский