1. Exploring the force-enhancing principle of toggle clamps

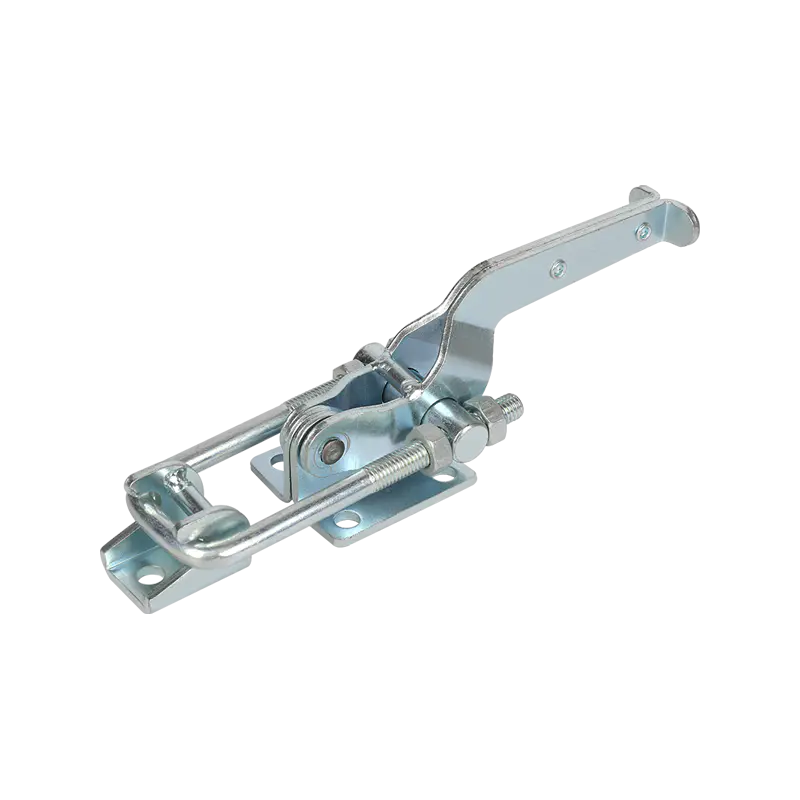

The reason why toggle clamps can achieve the magical effect of converting small operating forces into strong clamping forces during the clamping process lies in their exquisite toggle mechanism design. From the perspective of basic mechanical principles, the toggle mechanism utilizes the mechanical gain effect generated by the connecting rod at a specific angle. When the operating handle drives the toggle connecting rod to move, the direction and magnitude of force transmission change as the connecting rod angle changes. Near the end stroke of clamping, a lever-like structure is formed between the connecting rods. Through the clever transformation of the force arm, the input small operating force is multiplied, thereby generating a strong clamping force sufficient to firmly clamp heavy workpieces.

Take the common double-link toggle clamp as an example. When the user pulls the handle, the two connecting rods begin to move. In the initial stage, the connecting rod moves smoothly and the required operating force is relatively small. As the movement progresses, the connecting rod angle gradually decreases, and the force arm relationship changes, just like a lever that pries a boulder. Under the adjustment of the fulcrum and the force point position, a small force can generate a huge force at the force point. This force-enhancing effect is not a simple linear amplification, but based on the geometric characteristics and mechanical principles of the connecting rod mechanism, it realizes the efficient conversion and enhancement of force, laying a solid theoretical foundation for the outstanding performance of the quick release toggle clamp in heavy workpiece clamping operations.

2. Material and process create excellent performance

High-quality materials guarantee strength

Quick Release Hold Down Toggle Clamps have to take on the heavy task of clamping in high-demand occasions, and the choice of material is crucial. As one of the commonly used materials, high-carbon steel, with its high carbon content, gives the toggle clamp excellent strength and hardness. When facing workpieces weighing several tons or even heavier in the fields of heavy machinery manufacturing, large-scale construction, etc., the toggle clamp made of high-carbon steel can rely on its own high strength to steadily withstand huge pressure and tension, ensuring that key components such as the clamp arm and the shaft are not deformed or damaged during the clamping process.

Stainless steel toggle clamps show unique advantages in some environments that have special requirements for corrosion resistance and require a large clamping force. For example, in chemical production, various corrosive chemicals are diffused, and ordinary clamps are easily corroded and damaged. Stainless steel effectively resists corrosion with the dense oxide film formed by elements such as chromium and nickel in its alloy composition. At the same time, its good comprehensive mechanical properties can also ensure the provision of strong clamping force and maintain the stable operation of the production process.

Exquisite craftsmanship improves quality

As an important means of processing key components of toggle clamps, forging technology plays an important role in improving its performance. By applying strong pressure to the metal billet, it causes plastic deformation at high temperature, which not only shapes the required shape, but also significantly improves the internal structure of the metal. When forging components such as the clamp arm, precise control of the forging temperature, pressure and deformation can refine the metal grains and greatly improve the strength and toughness of the material. After multiple forgings and appropriate heat treatment process optimization, the clamp arm has high strength to withstand huge clamping force while also having a certain elasticity, which can better fit workpieces of different shapes and ensure the stability and reliability of clamping.

The machining process further carves out details for the high performance of the toggle clamp. A series of precision machining processes such as turning, milling, drilling, and grinding ensure the dimensional accuracy and surface quality of the parts. Turning ensures the high precision of the outer cylindrical surface of shaft parts, providing guarantee for precise matching with other parts; milling produces various shapes of structures such as the clamping surface and mounting holes of the chuck to meet different clamping and installation requirements; drilling provides precise holes for connection and positioning; grinding is for parts with extremely high matching accuracy requirements, such as the matching surfaces of the rotating shaft and the sleeve, to ensure the appropriate clearance, so that the toggle clamp is flexible and smooth during operation, reduce energy loss, and further improve the transmission efficiency of the clamping force.

3. Widely used in harsh fields

Solid guarantee for heavy machinery manufacturing

In heavy machinery manufacturing workshops, the processing of large parts is a difficult task. From huge engine blocks to heavy mechanical bases, these workpieces are not only large in size, but also incredibly heavy. Quick-release toggle clamps play a key role here, used to fix these heavy workpieces, ensuring that the workpieces can withstand strong cutting forces and maintain a stable position during turning, milling, boring and other processing processes. For example, when processing the crankshaft of a large ship engine, the crankshaft can weigh several tons. Through multiple quick-release toggle clamps made of high-carbon steel, it is firmly fixed on the machine tool workbench, allowing the machine tool to accurately perform complex processing operations on the crankshaft, ensuring processing accuracy and quality, and greatly improving production efficiency.

A reliable helper for construction

Construction sites also rely on the help of quick-release toggle clamps. During the construction of building structures, a large amount of heavy building materials need to be fixed. Taking the steel structure construction of high-rise buildings as an example, the installation of steel beams requires precise alignment and firm fixation. Quick-release toggle clamps can be used to temporarily fix steel beams. Construction workers can quickly operate the toggle clamps to clamp the steel beams in a predetermined position, which is convenient for permanent fixing operations such as welding or bolting. In the concrete pouring process, the toggle clamps used to fix large formworks must withstand the huge lateral pressure generated during concrete pouring. High-carbon steel or specially treated high-strength toggle clamps can stably clamp the formwork, prevent the formwork from deformation or displacement, ensure the dimensional accuracy and appearance quality of the concrete structure, and provide reliable protection for the smooth progress of construction.

Applications in other high-demand industrial scenarios

In the field of port logistics, when handling and temporarily fixing large containers or overweight goods, quick-release toggle clamps can be installed on professional handling equipment or fixtures to provide strong clamping force to prevent the goods from slipping during handling and ensure the safety of operations. In the manufacture and maintenance of some large mining equipment, large mechanical parts need to be clamped for repair and maintenance. The quick-release toggle clamp has greatly improved the maintenance efficiency and reduced the equipment downtime with its strong clamping force and convenient operation performance.

Fourth, the significant advantages of the quick-release toggle clamp

The perfect combination of strong clamping force and fast operation

The quick-release toggle clamp not only provides strong clamping force, but also has the characteristics of fast operation. Compared with some traditional tools that require long-term tightening or laborious operation to achieve a large clamping force, the toggle clamp, through a unique toggle mechanism design, can quickly establish and release the clamping force in a very short time by simply turning the handle. In heavy machinery manufacturing, when the workpiece is frequently replaced for processing, the advantage of this fast operation is extremely obvious, which greatly shortens the loading and unloading time of the workpiece, improves the actual processing time utilization rate of the machine tool, and thus improves the efficiency of the entire production process.

High reliability and stability

Due to the use of high-quality materials and advanced manufacturing technology, the quick-release toggle clamp shows extremely high reliability and stability when facing harsh working environments and high-intensity use. During the continuous long-term clamping operation of heavy workpieces, fatigue will not cause the clamping force to drop or the components to be damaged. At the construction site, the toggle clamp has to withstand wind and sun, dust erosion and frequent collisions, but it can still maintain stable clamping performance to ensure construction safety and quality. This high reliability and stability reduces equipment failures and maintenance times, reduces production costs, and provides strong support for the efficient production of enterprises.

Good versatility and adaptability

The quick-release toggle clamp is designed to be versatile and can adapt to the clamping needs of heavy workpieces of different shapes, sizes and materials. The chuck part is usually designed to be adjustable or replaceable. For workpieces of different shapes, the chuck angle can be adjusted or the chuck of a specific shape can be replaced, such as a V-shaped chuck for clamping round workpieces, a flat chuck for clamping flat workpieces, etc., to ensure the best clamping effect. Whether it is heavy mechanical parts made of metal or large workpieces made of wood or plastic, the quick-release toggle clamp can flexibly cope with various clamping tasks with its excellent versatility and meet the diverse needs of industrial production.

In summary, the quick-release toggle clamp has become an ideal choice for clamping heavy workpieces or requiring high clamping force due to its unique force-enhancing principle, high-quality materials and exquisite craftsmanship, a wide range of applications and significant advantages. With the continuous advancement and innovation of industrial technology, the quick-release toggle clamp will continue to optimize and develop, contribute greater strength to the efficient production and high-quality development of various industries, and shine more brightly on the future industrial stage.

English

English Español

Español русский

русский